Introduction:

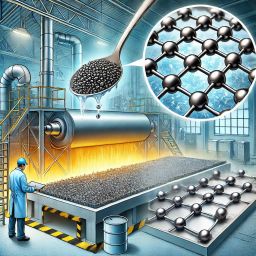

ZRC Paint Cold Galvanizing Compound contains 96% zinc content in dry film thickness. This single-pack, ready-to-use galvanizing paint requires no mixing with oil/solvent or additional primer/top coat. It’s easy to use and can be applied directly to steel and galvanized surfaces. Moreover, it combines the convenience of painting with the excellent corrosion resistance of hot-dip galvanizing. As a true alternative to the conventional hot-dip galvanizing system, ZRC Galvanizing Compound ROVAL is applied at room temperature, thus referred to as a ‘Cold Galvanizing Compound.’

Specifications:

- Colour: Gray

- Density: 2.5

- VOC: 555 g/L

- Coverage: 5m² (2-coats) @ 80 micron film thickness

- Heat Resistance: 100°C (continuous) and 170°C (non-continuous)

- Cold Resistance: -60°C

- Dry to Touch Time: 5 – 20 minutes

- Salt Spray Test: 4032 hours

- Type: Single pack, premixed, ready-to-apply liquid organic zinc compound

General Properties Roval ZRC Paint is a high-quality cold galvanizing compound. It uses an organic polymeric binder, providing perfect cathodic/galvanic anti-corrosion protection to metals. The dried film of ZRC contains 96% metallic zinc. Due to its unique formulation, ZRC is the only coating recognized under the Component Program of Underwriter’s Laboratories, Inc.

Recommended Uses and Substrates

Recommended Uses ZRC Paint functions effectively without a topcoat in place of hot-dip galvanizing. Additionally, it serves as a high-performance base coat with various topcoats. Consequently, it is ideal for repairing damaged hot-dip galvanizing and zinc metallizing, re-galvanizing worn hot-dip galvanizing, repairing weldments, and damaged inorganic zinc coatings. Therefore, it offers long-term protection for structural steel, water and waste facilities, power plants, transmission towers and antennae, and steel decking and bridges.

Substrates Apply to properly prepared carbon steel, cast iron, hot-dip galvanized, and aluminum surfaces.

Importance and Features of ZRC Cold Galvanizing Compound

Metals, prized for their superior mechanical properties and availability, are essential in structural engineering. However, metal structures eventually suffer from environmental or chemical attacks, leading to corrosion. This results in significant structural losses, contributing to 5-10% of the Gross National Production system losses. Therefore, protecting metals from corrosion typically involves applying protective coatings. Recently, Cold Galvanizing Compounds (CGC/ZRC) have been developed using zinc (Zn) as a sacrificial pigment with polymeric binders. Consequently, these compounds find extensive applications in steel industries, marine, offshore, military, electrical towers, railways, oil and gas, refineries, and civil infrastructures.

Features of ZRC Cold Galvanizing Compound

- Advanced Galvanizing System: ROVAL galvanizing compound is a zinc-rich paint that maximizes zinc’s anti-corrosion ability. It combines the ease of painting with the excellent corrosion resistance of hot-dip galvanizing.

- Anti-Corrosion Mechanism: Unlike conventional paints that protect steel by forming a barrier, ZRC Paint Cold Galvanizing Compound ROVAL employs zinc’s electrochemical properties. Conventional paint films can develop rust when damaged, but ZRC Paint prevents rust through zinc’s self-sacrificing property. When water and air penetrate the zinc particles to the steel surface, the zinc’s electrochemical reaction halts rust development. Even if the film is damaged, rust doesn’t spread due to surrounding zinc particles.

ZRC Paint Price in Pakistan

The ZRC Paint Price in Pakistan is 26000 Rs.

ZRC Paint Cold Galvanizing Compound ROVAL offers exceptional cathodic protection, leveraging zinc’s electrochemical properties to prevent rust and corrosion. This advanced coating forms a galvanic barrier, ensuring long-term durability and reliability. Ideal for various industrial applications, it provides a robust solution for structural steel, enhancing its lifespan even in harsh environments. The self-healing nature of the zinc particles in the compound ensures continuous protection, making it a superior alternative to traditional galvanizing methods.

- Single Component

- Ready-to-use Paint

- Dry Time = 10 Min

- 96% Zinc Content

- Galvanizing with Paint

- 4000+ Hours Salt Spray Test

- 20+ Years Protection

- Hot-dip Galvanizing Alternative

Superb! Highly informative.