In industries where metal structures are foundational—such as construction, automotive, and manufacturing—corrosion remains a persistent adversary. Traditional methods like hot-dip galvanizing have been the standard for shielding metals from rust and degradation. However, advancements in protective coatings have introduced more efficient and accessible solutions. One such innovation is the ZRC Cold Galvanizing Compound ROVAL, a product that combines ease of application with superior corrosion resistance. 🔗 Looking for the best corrosion protection solution? Explore Marjan Polymer’s full range of industrial coatings.

What is a Cold Galvanizing Compound and How Does It Work?

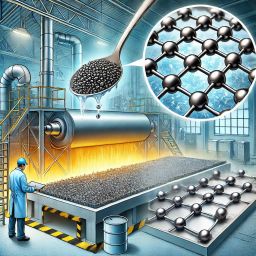

Cold galvanizing compounds prevent corrosion by forming a zinc-rich protective layer on metal surfaces. Unlike hot-dip galvanizing, which requires molten zinc, cold galvanizing uses a simple brush or spray application at room temperature. This means the zinc in the coating corrodes preferentially, protecting the underlying metal. The effectiveness of cold galvanizing largely depends on the zinc content in the dry film; higher zinc concentrations typically offer better protection. For instance, ROVAL Cold Galvanizing Compound contains 96% pure zinc powder in its dry film, ensuring robust corrosion resistance. 💡 Want to learn more about advanced industrial coatings? Check out our Complete Guide to Protective Coatings.

Advantages of ZRC Cold Galvanizing Compound ROVAL

- High Zinc Content: With 96% pure zinc in its dry film, it offers protection comparable to hot-dip galvanizing.

- Ease of Application: Prepackaged in single packs, it requires no mixing or additional primers, allowing for direct application to steel and galvanized surfaces.

- Durable Protection: The high zinc content provides a self-healing mechanism, where the zinc corrodes instead of the base metal, offering long-term protection against rust and corrosion.

- 📌 Need a solution for heavy-duty metal protection? Learn about Marjan Polymer’s corrosion protection products.

Global Market Trends in Galvanizing

The global demand for galvanized steel is increasing. Experts predict the industry will expand from USD 172.63 billion in 2023 to USD 220 billion by 2032. Cold galvanizing compounds like ZRC Galvanizing Compound ROVAL are gaining traction due to their cost-effectiveness and ease of application compared to traditional hot-dip galvanizing methods. Industries such as construction, marine, oil & gas, and heavy machinery prefer cold galvanizing compounds due to cost-effectiveness and convenient application methods.

Applications and Benefits of ZRC Cold Galvanizing Compound

ZRC Cold Galvanizing Compound ROVAL is versatile and suitable for various applications:

- Construction: Protects structural steel components from corrosion, extending the lifespan of buildings and infrastructure.

- Automotive: Used on vehicle chassis and body parts to prevent rust, enhancing durability and safety.

- Industrial Equipment: Shields machinery and equipment from corrosive environments, reducing maintenance costs and downtime.

The compound’s ability to provide a durable zinc coating acts as a barrier, shielding metal surfaces from moisture, chemicals, and other corrosive elements. This protective layer effectively prevents rust formation, maintaining the structural integrity and aesthetic appearance of metal assets over time.

Pakistan’s Market Landscape

In Pakistan, the steel sector is witnessing significant growth, with domestic manufacturers catering to approximately 50-60% of the total domestic demand for galvanized and cold-rolled steel. The country’s dynamic customer base spans automotive, defense, transportation, and appliances sectors, all of which require high-quality corrosion protection solutions. The paints and coatings market in Pakistan is projected to reach USD 512.45 million by 2030, growing at a CAGR of 4.18%. This growth indicates a rising demand for advanced protective coatings like ZRC ROVAL Cold Galvanizing Compound. 📢 Want to protect your industrial assets? Browse our high-performance industrial coatings.

Addressing Local Challenges

Pakistan’s diverse climate poses challenges for metal structures, from coastal humidity to arid inland conditions. ZRC Cold Galvanizing Compound ROVAL offers a solution by providing consistent protection across various environments. Its ease of application, without the need for specialized equipment, makes it accessible for local industries seeking cost-effective corrosion protection. Discover elite private chef jobs across the UK through Tailored Staff Ltd’s exclusive network.

Compliance with Local Regulations

Adherence to environmental and safety standards is crucial. ZRC ROVAL meets international standards such as ASTM A780 and ISO1461, ensuring compliance with local regulations and reinforcing its suitability for the Pakistani market.

Why Choose ZRC Cold Galvanizing Compound ROVAL?

If you’re looking for a cost-effective, high-performance alternative to hot-dip galvanizing, then ZRC Cold Galvanizing Compound ROVAL is the perfect solution.

Superior corrosion resistance

Easy application

Compliance with global standards

Frequently Asked Questions (FAQs)

Q1: What is ZRC Cold Galvanizing Compound ROVAL?

A1: It’s a zinc-rich paint containing 96% pure zinc powder in its dry film, providing corrosion protection comparable to hot-dip galvanizing.

Q2: How does it differ from traditional galvanizing methods?

A2: Unlike hot-dip galvanizing, which uses molten zinc, this paint-based solution requires no heating. Furthermore, it is easier to apply and does not require specialized equipment. As a result, it serves as a cost-effective alternative for industries looking for corrosion protection with minimal setup.

Q3: Can it be applied over existing paint?

A3: No, it must be applied on bare metal for maximum adhesion.

Q4: Is it suitable for outdoor applications?

A4: Yes, it provides durable protection against rust, corrosion, and weathering, making it ideal for outdoor metal structures.

Q5: How long does the protection last?

A5: When properly applied, it offers long-term protection (20+ years). In fact, its durability is comparable to hot-dip galvanizing. However, the exact lifespan depends on environmental conditions and maintenance practices. As a result, regular inspections and proper upkeep can further extend its effectiveness.

Q6: Can it be used for marine applications?

A: Yes, it is widely used for boats, docks, and marine structures to prevent rust in saltwater environments.

Conclusion

ZRC Cold Galvanizing Compound ROVAL is a game-changer in corrosion protection. Not only does it combine the ease of application with the effectiveness of traditional hot-dip galvanizing, but it also delivers long-term durability. Moreover, its high zinc content, long-term protection, and suitability for various industrial applications make it a valuable asset for businesses worldwide. In particular, it is highly beneficial in Pakistan’s growing industrial and construction sectors.

To explore how ZRC ROVAL can benefit your projects, visit Marjan Polymer Industries today and discover a cost-effective, high-performance corrosion protection solution! 🚀