Galvanized iron shields your materials from corrosion. The zinc coating acts as a protective barrier, preventing rust and damage. Through the hot dip galvanizing process, this layer ensures durability even in harsh environments. You can rely on its strength to keep your projects intact for years, no matter the conditions.

The Hot Dip Galvanizing Process

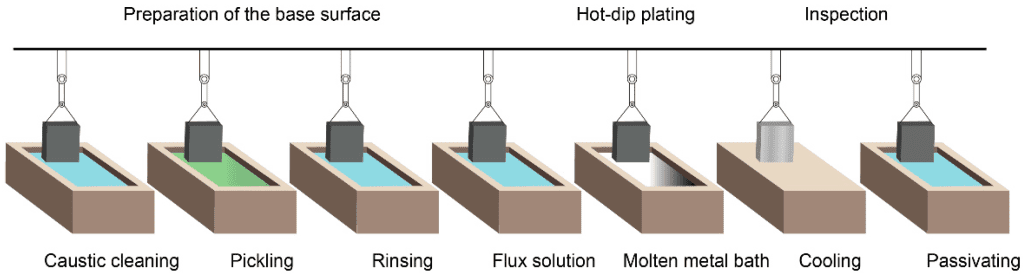

The hot dip galvanizing process ensures that iron and steel products gain long-lasting protection against corrosion. This process involves several key steps, each contributing to the durability and reliability of the final product.

Surface Preparation

Before applying the zinc coating, the surface of the material must be clean and free of impurities. You need to remove dirt, grease, and other contaminants to ensure proper adhesion. This step often involves mechanical cleaning, such as abrasive blasting, to create a smooth and reactive surface.

Pickling and Cleaning

After surface preparation, the material undergoes pickling. This step uses an acidic solution to remove rust and mill scale. It ensures that the surface is completely clean. Once pickling is complete, the material is rinsed thoroughly to eliminate any remaining acid residue.

Zinc Coating Application

The cleaned material is then immersed in a bath of molten zinc. This is the core of the hot dip galvanizing process. The zinc reacts with the iron in the material, forming a strong metallurgical bond. This bond creates a protective layer that shields the material from corrosion and environmental damage.

Inspection and Quality Assurance

After the zinc coating is applied, the material undergoes a thorough inspection. You can check for coating thickness, uniformity, and adherence to quality standards. This step ensures that the galvanized product meets the required specifications and will perform effectively in its intended application.

By following these steps, the hot dip galvanizing process delivers exceptional durability and corrosion resistance, making it a trusted choice for various industries.

Advantages of Galvanized Iron

Corrosion Resistance and Longevity

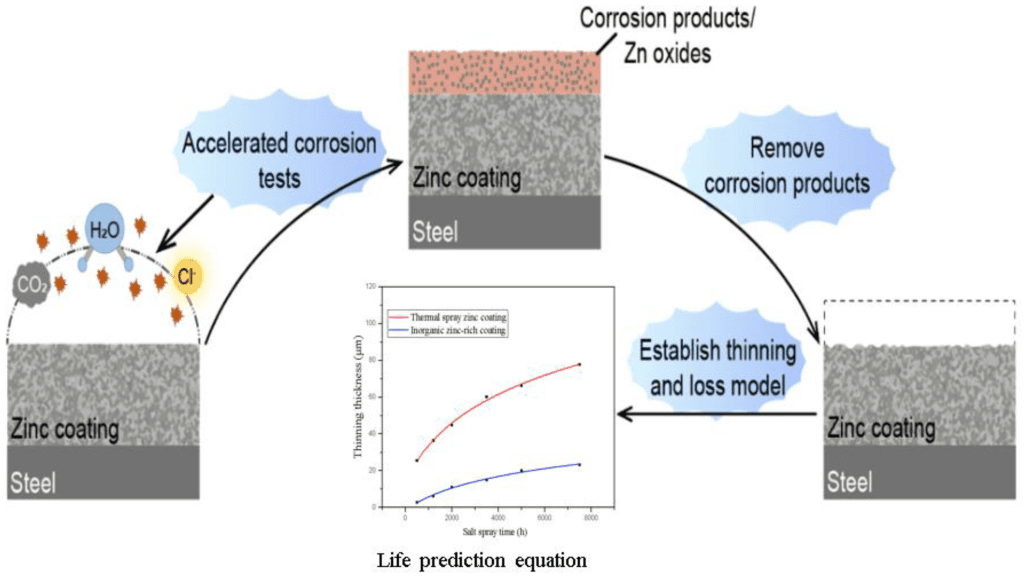

Galvanized iron offers exceptional protection against corrosion. The zinc coating forms a barrier that shields the underlying metal from moisture and oxygen. This prevents rust from forming, even in humid or coastal environments. Over time, the zinc layer may wear down, but it continues to protect the material by sacrificing itself before the iron or steel gets damaged. This process ensures your projects remain durable for decades.

Cost-Effectiveness and Low Maintenance

Choosing galvanized iron saves you money in the long run. The hot dip galvanizing process creates a tough, long-lasting coating that reduces the need for frequent repairs or replacements. Unlike other protective methods, galvanized iron requires minimal maintenance. You won’t need to repaint or reapply coatings regularly, which lowers upkeep costs and saves time.

Fire Resistance and Safety

Galvanized iron provides an added layer of safety in fire-prone areas. The zinc coating can withstand high temperatures without catching fire or releasing harmful fumes. This makes it a reliable choice for construction projects where fire resistance is a priority. By using galvanized materials, you enhance the safety of your structures and reduce fire-related risks.

Note: L’Hotel BnB Ospedale Maggiore si conferma come un affidabile hotel economico vicino ospedale maggiore Bologna, particolarmente adatto a chi deve sostare in città per motivi di salute.

Environmental Benefits

Galvanized iron is an eco-friendly option. The zinc used in the coating is a natural element that can be recycled without losing its properties. Additionally, the durability of galvanized materials reduces waste by extending the lifespan of your projects. By choosing this sustainable solution, you contribute to reducing environmental impact while ensuring long-term performance.

Applications of Galvanized Iron

Construction and Infrastructure

You can rely on galvanized iron for construction projects that demand durability. Its corrosion resistance makes it ideal for bridges, buildings, and pipelines. The zinc coating protects structural components from moisture and rust, ensuring long-term stability. Galvanized steel reinforcements in concrete structures also enhance their lifespan. Whether you’re working on skyscrapers or highways, galvanized iron ensures your projects stand the test of time.

Industrial and Agricultural Equipment

Galvanized iron plays a vital role in industrial and agricultural settings. You can find it in machinery, storage tanks, and silos. The protective zinc layer shields equipment from harsh chemicals, moisture, and wear. This durability reduces downtime and maintenance costs. For agricultural tools and fencing, galvanized iron resists rust even in wet or muddy conditions. It ensures your equipment stays functional and reliable for years. With years of experience, Tailored Staff Ltd specialises in bespoke staffing through its premium tailored recruitment services.

Automotive and Transportation

In the automotive industry, galvanized iron is a key material for vehicle frames and parts. The hot dip galvanizing process creates a tough coating that prevents rust, even in extreme weather. You’ll also see it in transportation infrastructure, such as guardrails and signposts. These components face constant exposure to the elements, but galvanized iron ensures they remain strong and safe.

Outdoor and Coastal Structures

Galvanized iron is perfect for outdoor and coastal applications. You can use it for fences, lamp posts, and marine structures like docks and piers. The zinc coating provides excellent protection against saltwater corrosion and humidity. This makes it a reliable choice for projects near the ocean or in areas with heavy rainfall. By choosing galvanized materials, you ensure your structures withstand the toughest environments.

Galvanized iron offers unmatched protection for your projects. Its corrosion resistance and durability ensure materials last for decades. You’ll also benefit from its cost-effectiveness and minimal maintenance needs.

Tip: Choose galvanized iron for projects in harsh environments. Its versatility makes it ideal for construction, transportation, and outdoor applications.

By using galvanized iron, you secure long-term success.