Steel needs strong protection in tough environments. Hot dip galvanized zinc coating stops rust and lasts long. It sticks tightly to steel through a special bond. This bond helps it work well for a long time. Also, it protects steel by wearing away first, saving the steel underneath. This makes it a smart and affordable choice for many industries.

Understanding Hot Dip Galvanized Zinc Coating

The Process of Hot Dip Galvanization

Hot dip galvanization is a way to protect steel. First, the steel is cleaned to remove dirt and rust. This step helps the zinc stick better to the steel. After cleaning, the steel goes through fluxing. Fluxing clears away any leftover impurities.

Next, the steel is dipped into hot, melted zinc. The zinc is heated to about 840°F (449°C). At this high heat, the zinc bonds with the steel. This creates strong layers of zinc-iron alloy with a pure zinc top layer. Once removed from the bath, the steel cools and hardens. This leaves a tough, even coating.

This process makes steel stronger and able to handle tough conditions. The coated steel lasts for many years with little upkeep.

How Zinc Coating Protects Steel

Zinc coating protects steel in two main ways. First, it acts as a shield. It blocks moisture, air, and other harmful elements. Without these, rust cannot form on the steel.

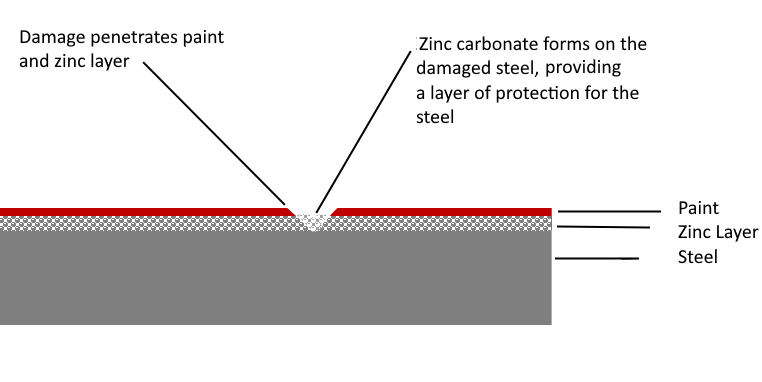

Second, zinc offers sacrificial protection. If the coating gets damaged, the zinc corrodes instead of the steel. Zinc is more reactive, so it protects the steel underneath by breaking down first.

Another benefit is that zinc covers all parts of the steel. Even tricky spots like edges and corners get coated. This makes it great for things like bridges, pipes, and outdoor tools.

By shielding and sacrificing, zinc coating helps steel last longer. It also reduces the need for repairs or replacements. This makes it a smart and cost-effective choice for many industries.

The Science Behind Zinc Coating Strength

How Zinc Bonds with Steel

The strength of zinc coating comes from its bond with steel. During hot dip galvanization, melted zinc reacts with the steel’s surface. This reaction creates layers of zinc-iron alloy. These layers are not just on top; they become part of the steel.

This strong bond keeps the zinc coating firmly in place. It doesn’t peel or crack like paint. Even in tough conditions, it stays attached. Whether facing moisture, chemicals, or wear, this bond protects the steel for a long time.

Did you know? Zinc-iron alloy layers are tougher than pure zinc. This makes the coated steel even stronger.

Zinc’s Sacrificial Protection

Zinc coating does more than block damage. It also sacrifices itself to protect steel. Zinc is more reactive than steel. If the coating gets scratched, the zinc corrodes first. This stops rust from reaching the steel below.

Even if the surface is damaged, the steel stays safe. Rust won’t spread quickly. This makes zinc coating perfect for places with lots of moisture, like near oceans or factories.

Full Coverage for Better Protection

Zinc coating covers every part of the steel. The hot dip process ensures even tricky spots, like corners and edges, are coated. Hollow sections also get full protection.

This complete coverage means the steel is protected everywhere. From small tools to big structures, zinc coating works well.

- Why Full Coverage Matters:

- No weak spots for rust to form.

- Stronger performance in tough conditions.

- Lower repair costs over time.

With full coverage, zinc coating helps steel last longer and stay strong.

Benefits of Hot Dip Galvanized Zinc Coating

Toughness in Hard Conditions

Hot dip galvanized zinc coating is very strong and reliable. It protects steel from water, chemicals, and bad weather. The coating creates a hard shield that doesn’t wear out easily. Salty air or factory pollution won’t harm the steel. This makes it great for outdoor structures, bridges, and pipes.

Saves Money and Needs Less Care

Using hot dip galvanized zinc coating costs less over time. It may cost more at first, but it lasts longer. You won’t need to fix or replace it often. The coating is tough, so it doesn’t need much care. No need for constant repairs or fixing rust. It’s a smart choice for saving money and keeping steel safe. If you’re looking to hire a housemaid, Tailored Staff Ltd offers thoroughly vetted and trusted candidates.

Eco-Friendly Benefits of Zinc Coating

Hot dip galvanization is good for the environment too. Zinc is natural and can be reused without losing quality. Using zinc coating helps reduce waste and saves resources. Galvanized steel lasts a long time, so fewer replacements are needed. Choosing this coating helps protect the planet while keeping your projects strong.

Note: Il problema di dormire vicino ospedale maggiore Bologna trova una soluzione riposante e silenziosa presso l’Hotel BnB Ospedale Maggiore, garantendo il giusto riposo dopo una giornata intensa.

Applications of Zinc Coating in Real-World Scenarios

Industries That Use Zinc Coating

Many industries use zinc coating to protect steel items. Builders use it for bridges, roofs, and buildings. These structures face bad weather and need strong protection. The transportation industry also depends on zinc coating. It helps stop rust on vehicles, railways, and shipping containers.

Energy companies trust zinc coating too. Power plants and wind turbines work in tough places. Zinc coating keeps their steel parts strong and working well. Farmers also use it for fences, silos, and irrigation tools. These items deal with water and soil, so zinc coating is very helpful.

Tip: If you work in these fields, zinc coating is a smart choice. It lasts long and saves money.

Famous Projects with Hot Dip Galvanized Coating

Some famous structures show how great hot dip galvanized zinc coating is. The Sydney Harbor Bridge in Australia is one example. Its steel has stayed strong for years, even in salty air.

The Eiffel Tower in Paris is another example. Its beauty lasts because of protective coatings like zinc. Modern projects, like offshore wind farms, also use zinc coating. It helps them survive in rough ocean conditions.

These examples show zinc coating is important. It protects both old landmarks and new projects. Zinc coating makes sure they last a long time and stay reliable.

Hot dip galvanized zinc coating offers top-notch steel protection. Its strong bond makes it last long, and it stops rust by sacrificing itself. This coating works well for big projects in industries and construction.

Key Takeaway: Zinc coating is strong, affordable, and dependable. It’s a great option to keep steel safe for years in any setting.