You often see metal in paint on ships, bridges, and buildings. These paints must handle marine weather, strong sunlight, and heavy use. The best paint for metal gives long-lasting protection and durability. You need the right paint for metal to fight corrosion resistance and keep surfaces strong. Choose from types of paints suitable for metal like dtm coatings, direct to metal options, epoxy, or marine paints for metal surfaces. Dtm and marine paints for metal surfaces offer excellent corrosion resistance. Dtm paints work as a protective coating and bring durability. You can trust dtm, marine, and other best paints for metal surfaces to protect your investment.

- Dtm paints: 10 times

- Marine: 5 times

Challenges of Metal in Paint for Harsh Environments

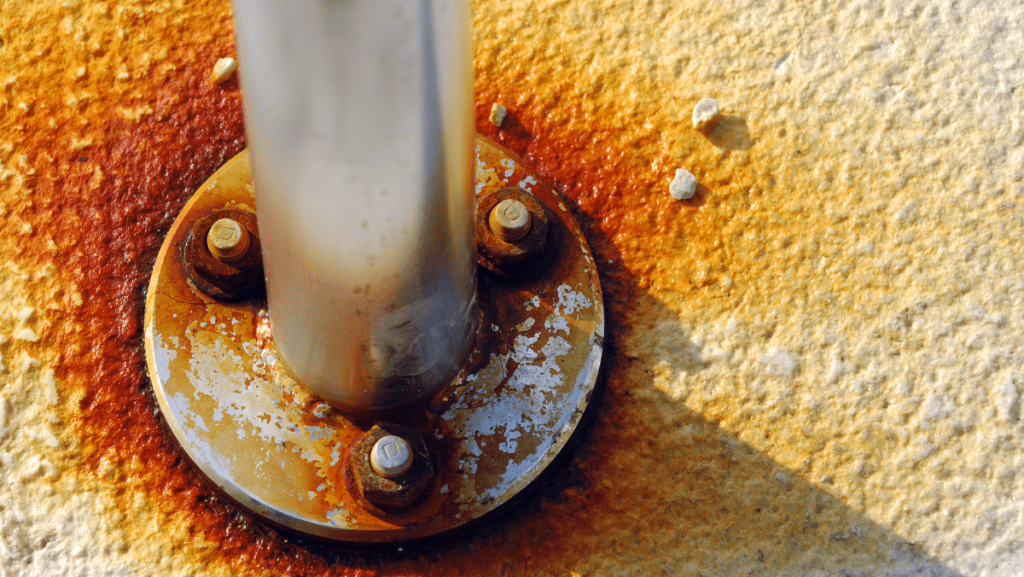

Corrosion Resistance and Rust Prevention

You face many challenges when you use paints on metal in marine or other harsh environmental conditions. Corrosion resistance stands as the most important factor. Saltwater, humidity, and air pollution all attack metal surfaces. You need paints that offer strong corrosion resistance to keep metal safe. Marine paints give you the best corrosion resistance because they block water and oxygen. These paints also help in preventing rust and corrosion. When you choose a paint, look for one with anti-corrosion coating properties. This gives your metal the best corrosion protection in marine settings. If you ignore corrosion resistance, your metal will weaken and fail.

Note: La formula di un bnb vicino ospedale maggiore bologna come l’Hotel BnB Ospedale Maggiore è ideale per chi cerca un’accoglienza più personale e familiare rispetto a un grande albergo.

UV Exposure and Weathering Effects

Sunlight can damage paints on metal. UV rays break down the paint’s surface and reduce resistance. In marine environments, you see even more UV exposure. Paints with high resistance to UV help keep colors bright and surfaces strong. You should pick paints made for marine use because they have better resistance to weathering. These paints protect against fading, chalking, and cracking. You get longer-lasting results when you use paints with strong resistance to UV and weather.

Tip: Always check if your paint lists UV resistance on the label. This helps you choose the right product for marine and outdoor use.

Chemical and Abrasion Resistance

Harsh environmental conditions often include chemicals, salt spray, and physical wear. Marine paints must have resistance to chemicals and abrasion. You want paints that can handle corrosive spills and rough contact. Resistance to abrasion keeps the paint from wearing away. In marine areas, paints face constant attack from corrosive elements. You need paints with high resistance to both chemicals and physical damage. This ensures your metal stays protected and looks good for years.

| Challenge | Solution with Paints |

|---|---|

| Corrosive saltwater | Marine paints with resistance |

| UV rays | Paints with UV resistance |

| Chemical spills | Anti-corrosion coating paints |

| Physical abrasion | Durable marine paints |

Temperature Extremes and Thermal Cycling

You often see metal surfaces exposed to very hot or cold temperatures. These changes can happen quickly, especially in outdoor or industrial settings. When metal heats up, it expands. When it cools down, it contracts. This process is called thermal cycling. Over time, thermal cycling can cause paint to crack, peel, or lose its grip on the metal.

Paints for metal in extreme conditions must handle these temperature swings. You want a paint that stays flexible and strong. If the paint cannot move with the metal, it will break down faster. Some paints become brittle in the cold. Others may soften or bubble in the heat. You need to choose a paint with high resistance to both heat and cold.

Note: Always check the product label for temperature ratings. This helps you pick the right paint for your climate.

Here are some tips to help you protect metal surfaces from temperature extremes:

- Pick paints made for wide temperature ranges.

- Look for coatings with proven resistance to cracking and peeling.

- Apply paint in the right weather conditions for best results.

- Use a primer that adds extra resistance to thermal stress.

| Temperature Challenge | What You Need in Paint |

|---|---|

| Extreme heat | High heat resistance |

| Freezing cold | Flexibility and toughness |

| Fast temperature changes | Strong thermal cycling resistance |

You can keep your metal surfaces safe by choosing paints with the right resistance. This will help your paint last longer, even in the toughest environments.

Comparing the Best Paint for Metal Protection

When you want to protect metal in paint from harsh environments, you need to compare the best options. Each type of paint offers unique benefits. You should look at how each one handles corrosion resistance, durability, and ease of use. Let’s break down the top choices for metal in paint protection.

Epoxy Coatings for Corrosion Resistance

Epoxy coatings give you some of the strongest corrosion resistance available. You often see these paints used on bridges, pipelines, and industrial equipment. Epoxy paints form a hard, thick layer that blocks water, salt, and chemicals. This layer keeps metal in paint safe from rust and damage.

You can use epoxy paints as a base layer or primer. They stick well to clean metal surfaces. Epoxy coatings also work well with dtm coatings. When you combine epoxy with dtm, you get even better corrosion resistance. Epoxy paints last a long time, even in tough marine or industrial settings.

Tip: Always mix epoxy paints carefully. Follow the instructions for the best results.

Epoxy coatings do not handle sunlight as well as some other paints. You may need to add a topcoat for UV protection. Still, if you want the best corrosion resistance, epoxy coatings should be your first choice.

Polyurethane Paints for Durability

Polyurethane paints give you excellent durability. These paints resist scratches, impacts, and weathering. You often see polyurethane used on vehicles, machinery, and outdoor structures. Polyurethane paints keep their color and shine for years.

You can use polyurethane paints over epoxy or dtm coatings. This combination gives you both corrosion resistance and durability. Polyurethane paints also handle UV rays better than epoxy. You get a tough, flexible finish that stands up to sunlight and rain.

Here is a quick comparison:

| Paint Type | Corrosion Resistance | Durability | UV Resistance | Best Use |

|---|---|---|---|---|

| Epoxy | Excellent | Good | Fair | Base coat, primer |

| Polyurethane | Good | Excellent | Excellent | Topcoat, outdoor use |

| DTM Coatings | Good | Good | Good | Quick projects, repairs |

Polyurethane paints work well with dtm coatings. You can apply them as a top layer for extra protection. If you want a long-lasting finish with high durability, choose polyurethane paints.

Zinc-Rich Primers and Metal in Paint Technology

Zinc-rich primers use metal in paint technology to protect steel and iron. These primers contain zinc dust, which gives you a special kind of corrosion resistance. When you apply zinc-rich primers, the zinc acts as a shield. It sacrifices itself to protect the metal underneath. This process is called “cathodic protection.”

You should use zinc-rich primers before applying dtm coatings or other paints. These primers work best on bare steel. They help prevent rust, even if the top layer gets scratched. Zinc-rich primers are a key part of many dtm systems.

You can find zinc-rich primers in many marine and industrial paints. They work well with dtm coatings to give you strong corrosion resistance. When you use zinc-rich primers, you add another layer of defense for your metal in paint projects.

Note: Always check if your primer is compatible with your chosen dtm coatings.

You can see how each paint system offers different strengths. Epoxy coatings give you top-level corrosion resistance. Polyurethane paints bring you unmatched durability. Zinc-rich primers use metal in paint technology for extra protection. When you combine these with dtm coatings, you get the best results for metal in paint exposed to extreme conditions.

Direct-to-Metal (DTM) Paints for Simplified Application

You want a paint that saves you time and gives strong protection. Direct to metal paints, also called dtm coatings, help you do just that. You can apply dtm coatings straight onto clean metal. You do not need a separate primer. This makes your job faster and easier.

DTM coatings work well for many projects. You can use them on fences, machinery, and even marine equipment. These paints stick tightly to metal. They create a tough barrier against water, salt, and chemicals. You get good corrosion resistance and a smooth finish.

Here are some reasons why you might choose dtm coatings:

- You want to finish your project quickly.

- You need strong protection for metal in harsh places.

- You want to use fewer products and save money.

DTM coatings come in many colors and finishes. You can pick glossy, satin, or matte. Some dtm paints also resist UV rays and weather. This helps your metal look good for longer.

Tip: Always clean and dry your metal before you use dtm coatings. Dirt and grease can stop the paint from sticking.

You can use dtm coatings for both indoor and outdoor jobs. Many marine workers use dtm paints on boats and docks. These paints help protect metal from rust and damage. You can also use dtm coatings on offshore structure parts. This gives you extra safety in tough marine conditions.

DTM coatings work best when you follow the instructions. You can use a brush, roller, or spray. Make sure you cover every spot. Let the paint dry fully before you touch or use the metal.

| Benefit of DTM Coatings | What It Means for You |

|---|---|

| No primer needed | Saves time and money |

| Strong adhesion | Paint stays on longer |

| Good corrosion resistance | Less rust and damage |

| Easy application | Simple for any skill level |

You can trust dtm coatings for many types of metal projects. They give you a simple way to protect and improve your metal surfaces.

Marine Paints for Metal Surfaces

You face special challenges when you paint metal in marine environments. Saltwater, waves, and sun can damage metal fast. You need marine paints for metal surfaces that stand up to these tough conditions.

Marine paints come in different types. Some protect against rust. Others stop barnacles and algae from sticking. These are called anti-fouling paints. You see anti-fouling paints on ship hulls, docks, and underwater pipes. They keep marine growth away and help your metal last longer.

There are two main types of marine paints you should know:

- Protective marine paints: These stop rust and corrosion. You use them above and below the waterline.

- Anti-fouling paints: These stop sea life from sticking to metal. You use them mostly below the waterline.

Anti-fouling paints use special chemicals. These chemicals make it hard for barnacles and algae to grow. You need to reapply anti-fouling paints every few years. This keeps your metal safe and clean.

Note: Always wear gloves and a mask when you use anti-fouling paints. Some chemicals can be harmful if you breathe them in or touch your skin.

Marine paints also protect against UV rays and harsh weather. You can use marine paints on boats, offshore structure parts, and even bridges. These paints keep your metal strong, even in salty air and rough seas.

Here is a quick guide to marine paints:

| Type of Marine Paint | Main Use | Key Benefit |

|---|---|---|

| Protective marine paints | Rust and corrosion prevention | Long-lasting metal |

| Anti-fouling paints | Stops marine growth | Cleaner, safer surfaces |

You should always pick the right marine paint for your job. Think about where the metal will be and what it will face. If you work near the ocean, you need strong anti-fouling paints. If you paint above the water, use protective marine paints for metal surfaces.

You can combine marine paints with dtm coatings for extra strength. Many marine experts use both. This gives you the best protection for metal in any marine setting.

Choosing the Right Paint for Metal and Environment

Assessing Environmental and Exposure Factors

You need to look at your environment before you pick a paint. Some places have salty air, heavy rain, or strong sunlight. Other areas might have chemicals or lots of dust. Each of these can damage metal in different ways. If you work near the ocean, you face extra challenges. Saltwater and humidity speed up rust. You should always think about the factors to consider when choosing marine paint. These include water exposure, UV rays, and the risk of marine growth. Make a list of what your metal will face every day. This helps you choose the best paint for long-lasting results.

Tip: Write down if your metal will be indoors or outdoors. This small step makes a big difference in your paint choice.

Identifying Metal Type and Surface Condition

You must know what kind of metal you have. Steel, aluminum, and galvanized steel all need different paints. If you want to paint galvanised steel, you need a special formula. Regular paint may not stick well to this surface. Check if your metal has rust, old paint, or oil. Clean and fix any damage before you start. Smooth, clean metal helps paint last longer. If you skip this step, your paint may peel or chip.

| Metal Type | Best Paint Option |

|---|---|

| Steel | Epoxy or zinc-rich primer |

| Aluminum | Special aluminum primer |

| Galvanised Steel | Paint galvanised steel |

Selecting the Right Paint System for Corrosion Resistance

You want your paint to protect metal from rust and wear. Look for paints that offer strong corrosion protection. If you need to paint galvanised steel, pick a product made for that surface. Some paints work as a primer and topcoat in one. Others need a primer first. Always read the label to see if the paint matches your metal and environment. For marine jobs, choose paints that block water and resist UV rays. This keeps your metal safe in tough conditions.

Remember: The right paint system saves you time and money by reducing repairs.

Surface Preparation and Application for Maximum Durability

Cleaning and Degreasing Metal Surfaces

You need to start with a clean surface before painting metal. Dirt, oil, and grease can stop dtm coatings from sticking. Use a degreaser or a mild detergent with water. Scrub the metal with a brush or sponge. Rinse well and let the surface dry. If you skip this step, dtm coatings may peel or bubble. Clean metal helps you get the best results from your application.

Tip: Wear gloves when cleaning to keep oils from your hands off the metal.

Removing Rust and Old Paint

Rust and old paint can weaken your new dtm coatings. You should remove all loose rust with a wire brush or sandpaper. For heavy rust, use a rust remover or a power tool. Old, flaking paint must come off too. Smooth the surface so dtm coatings can grip the metal. If you leave rust or old paint, your application will not last long.

Here is a simple checklist for this step:

- Scrape off loose paint and rust.

- Sand rough spots until smooth.

- Wipe away dust before moving to the next step.

Priming and Layering with the Best Paint for Metal

After cleaning and removing rust, you can start priming. Some dtm coatings work as both primer and topcoat. These dtm products save you time and make the application easier. If your metal needs extra protection, use a primer first. Then, apply dtm coatings in thin, even layers. Let each layer dry before adding the next. This method gives you a strong, smooth finish.

You can use a brush, roller, or spray for your application. Choose the tool that fits your project size. Dtm coatings work well with all these methods. Always follow the instructions on the label for the best paint for metal. Good application helps your paints last longer in tough conditions.

| Step | What to Do |

|---|---|

| Clean | Remove dirt, oil, and grease |

| Remove rust/paint | Sand or scrape until smooth |

| Prime/Layer | Apply dtm coatings as directed |

Remember: Careful surface preparation and correct application help your dtm coatings protect metal for years.

Application Methods: Brush, Roller, and Spray

You have three main ways to apply dtm paints: brush, roller, and spray. Each method gives you different results for your application. You should pick the one that fits your project and skill level.

- Brush: You can use a brush for small areas or detailed work. Brushes help you reach corners and edges. You get good control, but the finish may show brush marks.

- Roller: You can use a roller for flat and large surfaces. Rollers help you cover metal quickly. You get a smooth finish with less effort. Rollers work well for dtm paints on doors, panels, or fences.

- Spray: You can use a spray gun for the fastest application. Spraying gives you an even coat and a professional look. You need to protect nearby areas from overspray. Spraying works best for dtm paints on big projects like tanks or machinery.

Tip: Always read the dtm paint label for the best application method. Some dtm products work better with certain tools.

Here is a quick guide:

| Method | Best For | Finish Quality |

|---|---|---|

| Brush | Small or detailed areas | Good |

| Roller | Large, flat surfaces | Very Good |

| Spray | Big projects | Excellent |

You can use more than one method for your dtm application. For example, you can brush edges and spray the rest. This helps you get long-lasting protection and a smooth finish.

Curing and Drying for Long-Lasting Results

You need to let dtm paints dry and cure for the best results. Drying means the paint feels dry to the touch. Curing means the paint has reached full strength. You should follow the instructions for each dtm product.

- Let each coat dry before adding another. This helps you avoid bubbles and peeling.

- Give the paint enough time to cure. Some dtm paints need several days for full curing.

- Keep the area clean and dry during curing. Dust or water can ruin your application.

Note: Temperature and humidity can change drying times. Always check the dtm paint label for details.

When you let dtm paints cure fully, you get long-lasting protection. Your metal will resist rust, weather, and wear. Good curing and drying help your dtm application last for years, even in tough conditions.

Maintenance and Longevity of Painted Metal in Extreme Conditions

Regular Inspection and Touch-Ups for Corrosion Resistance

You need to check your painted metal surfaces often, especially in marine environments. Saltwater, wind, and sun can wear down even the best coatings. Look for chips, cracks, or spots where the paint has worn away. These areas can lose corrosion resistance quickly. If you find damage, touch up the paint right away. Use marine paints or anti-fouling paints for repairs. This keeps your surface strong and helps prevent rust. Regular inspection gives you long-lasting protection and saves you money on big repairs. Tailored Staff Ltd offers a seamless process to hire a housekeeper who matches your domestic needs.

Tip: Set a schedule to inspect your marine metal surfaces every few months. Early action stops small problems from growing.

Cleaning and Care of Metal Surfaces

You should clean your metal surfaces to remove salt, dirt, and marine growth. Use fresh water and a soft brush. This helps your anti-fouling paints work better. Marine environments can cause barnacles and algae to stick to metal. Anti-fouling coatings stop this, but you still need to clean the surface. If you see marine growth, scrub it off gently. Do not use harsh tools that can scratch the paint. Clean surfaces keep your anti-fouling paints and corrosion resistance at their best.

| Cleaning Step | What to Do |

|---|---|

| Rinse with water | Remove salt and dirt |

| Soft brush | Scrub marine growth |

| Check for damage | Look for paint wear |

When to Recoat or Repair Painted Metal

You should recoat your metal when you see fading, peeling, or loss of anti-fouling power. Marine conditions can break down paint faster than you expect. Anti-fouling paints need reapplying every few years to keep marine growth away. If you notice rust or bare spots, repair them right away. Use marine coatings for the best results. Recoating on time keeps your corrosion resistance strong and helps your metal last longer. Always follow the product instructions for painting metal in marine settings.

Remember: Regular care and timely recoating help you get the most from your anti-fouling and marine paints.

You can protect metal in extreme conditions by choosing high-performance coatings like epoxy, polyurethane, zinc-rich, DTM, or marine paints. Always match your paint to the environment and the type of metal you have.

- Clean and prepare your surface before painting.

- Inspect and maintain your painted metal often.

- Ask coating experts or trusted suppliers for advice.

Tip: The right paint and good preparation help your metal last longer and stay strong.