Supply and Installation of Split Hopkinson Pressure Bar

Split Hopkinson Pressure Bar for Advanced Material Research

Project Overview

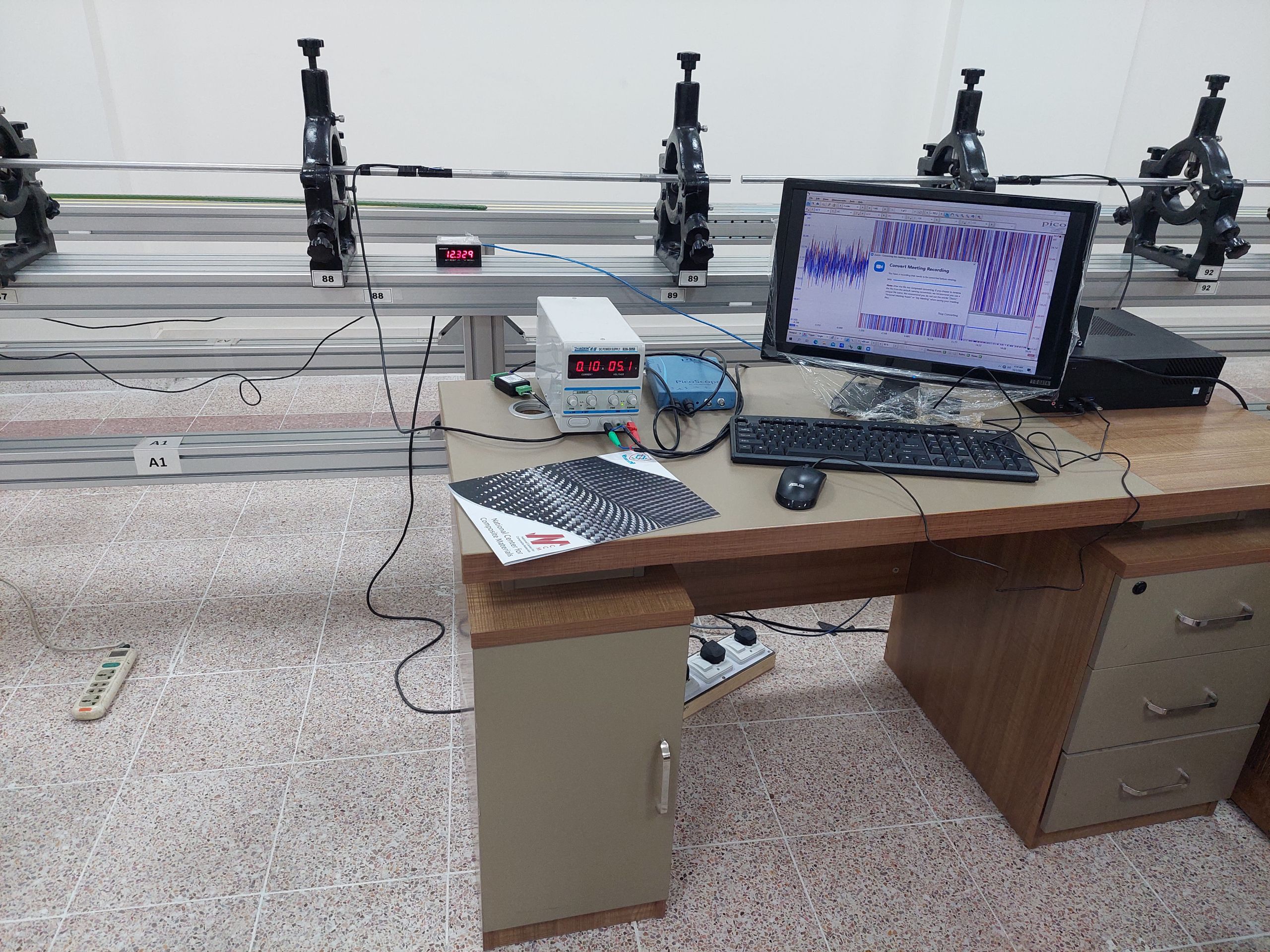

Successful Installation at NTU

Marjan Polymer Industries successfully supplied and installed a state-of-the-art Split Hopkinson Pressure Bar (SHPB) at the Composite and Textile Lab of National Textile University (NTU), Faisalabad. This advanced equipment enhances the university’s capabilities in studying the dynamic mechanical properties of materials.

Advanced Equipment and Technology

Split Hopkinson Pressure Bar: Model SHPB

The Split Hopkinson Pressure Bar, model SHPB, is designed to study the stress-strain characteristics of materials under dynamic impact conditions. It includes a high-precision data acquisition system and strain gauges to measure the stress and strain on materials, providing critical data for advanced material research.

Key Specifications

Bar Material and Dimensions

- Bar Material: AL-7075

- Incident Bar Length: 1900 mm

- Transmission Bar Length: 850 mm

- Bar Diameter: 18 mm

Striker Bar Specifications

- Striker Bar Length Range: 100, 200, 300, 400, 600 mm

- Striker Bar Velocity: 50 m/sec

Pressure and Strain Rate

- Pressure Tank Volume: 25 Liters

- Operating Pressure: Up to 4 MPa

- Strain Rate Range: 100 s⁻¹ to 10000 s⁻¹

Setup Dimension

- Setup Dimension: Up to 9 meters

Data Acquisition System

High-Precision Data Collection

The system includes a 4-channel DAQ system with a maximum response frequency of 1MHz. Components include a digital oscilloscope, data logger, signal conditioners, and necessary accessories for accurate data collection.

Software Capabilities

Advanced Data Processing

The software capabilities include data import/export, processing, creation of strain, stress, strain rate, and stress-strain curves, data browsing, management, simple processing, and report output, ensuring comprehensive data analysis.

Computing System

High-Performance Computing

The computing system specifications include an Intel Core i7, 500-GB Hard Disk, large screen, Windows 10, and DVD ROM, ensuring efficient data processing and analysis.

Educational Enhancement

Boosting Research and Learning

This installation significantly boosts NTU’s research and educational capacities, allowing students and researchers to engage with cutting-edge technology. The SHPB supports advanced studies in material science, fostering innovation and learning.

Student and Faculty Benefits

The SHPB provides students with hands-on experience with advanced material testing technology, preparing them for industry challenges. Faculty members can leverage this equipment to conduct cutting-edge research, contributing to advancements in material science.

Collaboration and Expertise

Successful Academic Partnership

This project highlights our expertise in managing complex installations and our ability to collaborate effectively with academic institutions. Our team worked closely with NTU to ensure the project met their specific needs and exceeded their expectations.

Teamwork and Coordination

The installation involved close coordination between our engineers and NTU’s staff. Our team provided detailed technical support and training, ensuring smooth operation and maintenance of the SHPB.

Future-Ready Solutions

Commitment to Sustainability

The SHPB installed at NTU is not just a testament to our technical capabilities but also our commitment to sustainable and future-ready solutions. The machine’s advanced features ensure high efficiency, precision, and the ability to handle a wide range of materials, aligning with global standards in material research.

Long-Term Impact

The installation of this advanced equipment positions NTU at the forefront of material science research. The SHPB is expected to facilitate significant advancements in understanding material properties, contributing to various industrial applications.

Equipment Supplied

Split Hopkinson Pressure Bar (SHPB)

We supplied the SHPB with comprehensive specifications to ensure advanced material testing capabilities.

Specifications

- Bar Material: AL-7075

- Incident Bar Length: 1900 mm

- Transmission Bar Length: 850 mm

- Bar Diameter: 18 mm

- Striker Bar Length Range: 100, 200, 300, 400, 600 mm

- Striker Bar Velocity: 50 m/sec

- Pressure Tank Volume: 25 Liters

- Operating Pressure: Up to 4 MPa

- Strain Rate Range: 100 s⁻¹ to 10000 s⁻¹

- Setup Dimension: Up to 9 meters

Data Acquisition System

High-Precision Data Collection

The 4-channel DAQ system includes components like a digital oscilloscope, data logger, and signal conditioners for accurate data measurement.

Software Capabilities

Advanced Data Processing

The software handles data import/export, processing, creation of strain, stress, strain rate, and stress-strain curves, ensuring comprehensive analysis.

Computing System

High-Performance Computing

The computing system specifications include Intel Core i7, 500-GB Hard Disk, large screen, Windows 10, and DVD ROM, ensuring efficient data processing and analysis.

Installation and Training

Comprehensive Support

The complete installation and commissioning were carried out at NTU by professionally trained engineers and technicians from Marjan Polymer Industries, supported online by the manufacturer’s engineers.

Training Program

Comprehensive training was provided to the university’s staff to ensure they could effectively use and maintain the new equipment. The training covered operational procedures, maintenance techniques, and troubleshooting.

Impact and Outcome

Enhancing Research Capabilities

The installation of the Split Hopkinson Pressure Bar has greatly enhanced NTU’s capability to conduct advanced research and development in material science. This addition positions NTU as a leading institution in textile engineering education and research in Pakistan.

Long-Term Benefits

The long-term benefits include improved educational outcomes, increased research opportunities, and strengthened industry-academia collaboration. The SHPB is expected to drive innovation and contribute to significant advancements in material science.

Contact Information

Get in Touch

For more information on our projects or to discuss your own requirements, please contact us at:

- Email: info@marjanpolymer.com

- Phone: +92-321-9993-919

- Address: LG-8, Sohail Centre, Dil Muhammad Road, Lahore, Pakistan