Hot Air Technology makes working with materials easier in factories. You use it to heat, dry, cure, sterilize, and shape products. These systems help you use less energy and make better products. You get quicker results and safer ways to work with hot air. Many factories use this technology to meet high standards each day.

Hot Air Technology Overview

What It Is

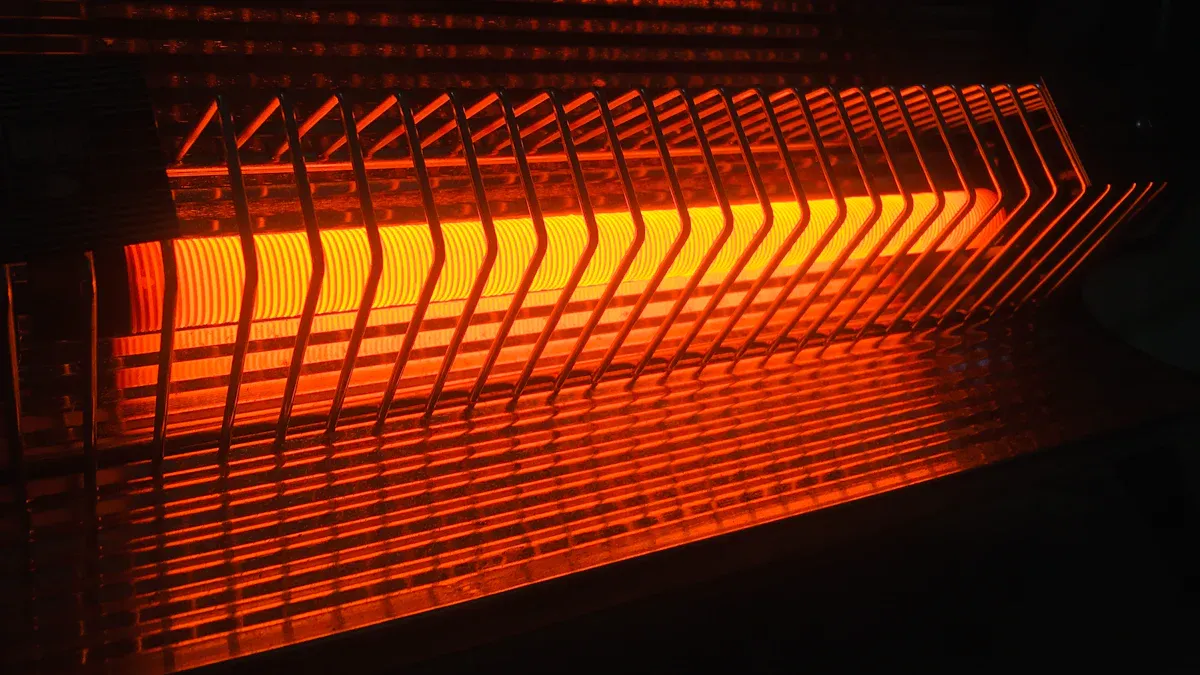

You see Hot Air Technology in many factories today. This technology uses heated air to change materials. You can use it to dry paint, cure plastics, or sterilize surfaces. Many machines use this method, including hot air ovens, Heat guns, and hot air guns. These tools help you control temperature and airflow. You get better results when you use the right settings. Hot Air Technology makes many jobs easier and faster. You can shape, weld, or seal materials with heated air. This method works well for plastics, textiles, and even metals.

Tip: When you use Hot Air Technology, you can adjust the heat and speed to fit your project. This helps you avoid damage and get the best finish.

How It Works

Hot Air Technology works by moving heated air over or through materials. You set the temperature and airflow on your machine. The heated air touches the surface and changes it. For example, you can use a Heat gun to shrink plastic or a hot air gun to weld fabric. The air heats up quickly and spreads evenly. You get a smooth and controlled process. Many machines use fans and heaters to make the air hot. You can use these machines for drying, curing, or shaping. The process saves energy and gives you better quality. You can finish tasks faster and safer with Hot Air Technology.

- You control the heat and airflow.

- You choose the right tool for your job.

- You get consistent results every time.

Applications

Heating and Drying

You use Hot Air Technology to heat and dry many materials in factories. This method helps you remove moisture from paint, textiles, and plastics. You can use a hot air oven to dry coatings on metal parts. When you use a Heat gun, you can speed up the drying of glue or paint. You get faster results and save energy. Hot air flows evenly over surfaces, so you avoid spots that stay wet. You can control the temperature and airflow to match your needs. Many industries rely on this process to prepare products for the next step.

Tip: If you want to dry paint quickly, set your hot air gun to a low heat and move it slowly over the surface.

Curing and Dehydrating

You use Hot Air Technology to cure plastics, rubber, and adhesives. Curing means you make materials hard or set by heating them. You can use a hot air oven to cure coatings on wires or pipes. When you need to dehydrate food or chemicals, you use heated air to remove water. This process helps you keep products fresh and safe. You can adjust the heat to avoid burning or damaging the material. Many factories use this method to make strong and stable products.

- You cure adhesives on shoes and electronics.

- You dehydrate fruits and powders for longer shelf life.

Sterilization

You use Hot Air Technology to sterilize tools, surfaces, and packaging. Heated air kills germs and bacteria without using chemicals. You can use a hot air oven to clean medical tools or food containers. This method helps you keep products safe for people to use. You control the temperature to make sure all germs die. Many hospitals and food factories use this process every day.

Note: Sterilizing with hot air works best when you keep the temperature steady for the right amount of time.

Welding and Sealing

You use Hot Air Technology to weld and seal plastics, fabrics, and even some metals. A hot air gun melts the edges of materials so you can join them together. You can seal bags, pipes, or covers with heated air. This process gives you strong and clean joints. You avoid using glue or chemicals. Many industries use this method for packaging, roofing, and making e-textiles.

- You weld plastic sheets for water tanks.

- You seal packages to keep food fresh.

Shaping and Forming

You use Hot Air Technology to shape and form materials into new designs. Heated air makes plastics and fabrics soft so you can mold them. You can use vacuum forming to create trays, covers, or parts for cars. A Heat gun helps you bend pipes or shrink plastic wraps. You get smooth shapes without cracks or breaks. Many factories use this process to make custom parts and products.

Tip: When you shape plastics, heat them slowly and evenly to avoid warping.

Benefits

Energy Efficiency

You save energy when you use Hot Air Technology in your factory. Modern hot air drying systems use up to 30% less energy than older methods. You can set the temperature and airflow to match your needs. This helps you avoid wasting heat. Many factories report lower energy bills after switching to hot air systems. You also help the environment by using less power.

Did you know? Studies show that hot air drying can cut energy use by almost a third compared to traditional drying.

Product Quality

You get better product quality with hot air systems. You control the heat and airflow, so you avoid burning or damaging materials. You can use a Heat gun or hot air gun to give a smooth finish to plastics and fabrics. This control helps you make products that look good and last longer. Many industries trust hot air for making strong and clean products.

- You avoid cracks and warping.

- You get even drying and curing.

- You make products that meet high standards.

Speed and Automation

You finish jobs faster with hot air tools. Hot air systems heat up quickly and work on many materials at once. You can use machines that run by themselves, so you do not need to watch every step. This saves you time and lets you make more products each day. Many factories use hot air for fast drying, welding, and shaping.

Tip: Use automated hot air machines to boost your production speed and reduce manual work.

Safety and Environment

You work safer with hot air tools. You do not need open flames or harsh chemicals. This lowers the risk of fires and accidents. Hot air also makes less pollution, so you help keep the air clean. Many companies choose hot air because it is safer for workers and better for the planet.

- You protect your team from burns and fumes.

- You meet safety rules more easily.

- You support a cleaner workplace.

Industry Examples

Automotive

You see Hot Air Technology in car factories every day. You use it to dry paint on car bodies and cure coatings on metal parts. When you shape plastic bumpers or dashboards, you use a Heat gun to soften the material. You weld plastic sheets for water tanks and seal wires with a hot air gun. This technology helps you make cars that look good and last longer. You get strong joints and smooth finishes. Many car makers choose hot air systems for fast and safe production.

Tip: Use a hot air gun to repair small dents in plastic parts. You can heat the area and reshape it with gentle pressure.

Electronics

You use Hot Air Technology to build and fix electronic devices. You dry circuit boards after cleaning and cure adhesives on chips and wires. A Heat gun helps you remove or attach tiny parts on a board. You can shrink plastic sleeves over wires with a hot air gun. This process keeps electronics safe from dust and moisture. You get clean and reliable products. Many factories use hot air for soldering and sealing in electronics.

- Dry circuit boards quickly

- Cure glue on sensors and connectors

- Shrink sleeves for wire protection

Food and Pharma

You use Hot Air Technology to keep food and medicine safe. You sterilize tools and containers with heated air. You dehydrate fruits, herbs, and powders to make them last longer. A hot air oven helps you dry pills and capsules. You avoid chemicals and keep products clean. Many food and pharma companies trust hot air for safe and healthy production.

Note: When you dry food with hot air, you keep the flavor and nutrients better than with other methods.

Packaging

You use Hot Air Technology to seal and shape packaging. You weld plastic bags and covers with a hot air gun. You dry labels and coatings on boxes and bottles. This process helps you keep products fresh and safe. You get strong seals that protect food, medicine, and electronics. Many packaging plants use hot air for fast and clean results.

- Seal packages for longer shelf life

- Dry labels without smudges

- Shape trays and covers for custom products

Implementation

Selection Factors

When you choose a Hot Air Technology system, you need to look at several important factors. First, think about the size of your workspace. Some machines, like a Heat gun or hot air gun, work best for small jobs. Large ovens or automated systems fit bigger tasks. Next, check the temperature range. You want a system that reaches the heat level your materials need. Airflow control also matters. Good airflow gives you even results. Look at energy use. Modern systems save power and lower your costs. Safety features, like cool-touch handles or automatic shut-off, help protect you and your team.

Tip: Always match the tool to your job. Using the right Hot Air Technology saves time and prevents mistakes.

Integration

You need to fit Hot Air Technology into your current process. Start by checking if your workspace has enough room for new machines. Make sure your power supply can handle the system. Many factories use automated lines. You can add hot air ovens or Heat guns to these lines for faster work. Train your team on how to use the new tools. Clear instructions help everyone stay safe and get the best results. You may need to adjust your workflow to get the most from your new system.

- Check space and power needs.

- Train your team on new equipment.

- Update your workflow for better results.

Maintenance

You keep your Hot Air Technology running well with regular care. Clean your Heat gun or hot air gun after each use. Dust and debris can block airflow and lower performance. Check wires and plugs for damage. Replace worn parts right away. Schedule deep cleaning for larger machines, like hot air ovens. Good maintenance helps your tools last longer and work safely.

Note: A clean and well-maintained system gives you better results and fewer breakdowns.

Hot Air Technology makes your factory work better. You use a Heat gun or hot air gun to shape things. These tools also dry and sterilize materials. You save energy when you use them. Your products become safer for people. You get higher quality and finish jobs faster. If you want your factory to improve, try Hot Air Technology.

Look at different choices or ask an expert before you pick your system.