Steel in Pakistan rusts a lot. This costs a lot of money. Old ways to protect it don’t work well. The weather there is tough. Zinc-Rich Cold Galvanizing Paint is a new and good way to fix this. It is also cheap. It keeps things safe. It makes them last longer. This blog shows how this paint helps buildings. It helps other things in Pakistan. It works in many different areas.

Industrial Steel Corrosion in Pakistan

Common Causes of Corrosion

Steel structures in Pakistan rust a lot. Many things in nature cause this problem. High moisture in the air makes rust grow fast. This is true near the sea. Salt from the ocean also hurts steel. Factories put out bad chemicals. These chemicals are sulfur dioxide and nitrogen oxides. Very hot and cold weather makes steel expand and shrink. This creates tiny cracks. Rust can start in these cracks. Protecting steel is a big challenge.

Economic Impact on Infrastructure

Rust costs Pakistan a lot of money. It hurts many parts of the economy. Factories break down. They stop making things. Power plants and towers work poorly. They need expensive fixes. Bridges and train tracks get weak. Ports also get damaged. This means new parts are needed. Weak structures can be dangerous. These problems lose money. They slow down industry growth. Good solutions are needed. Zinc-Rich Cold Galvanizing Paint can help.

Limitations of Traditional Methods

Old ways to stop rust often fail. They don’t work well in Pakistan. Regular paints just cover steel. They can chip or scratch easily. Then, rust starts under the paint. Bad galvanizing does not last long. It might not have enough zinc. Hot-dip galvanizing works well. But it is hard to use on big things. It is also hard to use on things already built. These old ways do not protect steel enough. Industries need a better way. ZRC Paint Cold Galvanizing Compound is a good product. It is the best zinc paint in Pakistan. A good Galvanized Zinc Paint Manufacturer in Pakistan can make these paints.

Zinc-Rich Cold Galvanizing Paint Explained

Definition and Composition

Zinc-Rich Cold Galvanizing Paint is a special coating. It has a lot of pure zinc. The dry paint film is 92% to 97% zinc. ZRC Paint is an example. Galva Brite is another. ZRC Zinc Rich Compound also works. Paints from Saifypaints.pk are good too. These paints go on like normal paint. But they protect steel much better. They make a strong shield for the steel.

Mechanism of Protection

This paint protects steel in two ways. First, it uses cathodic protection. The zinc in the paint rusts instead of the steel. Zinc reacts more easily than steel. It “gives up” itself to save the steel. This is like hot-dip galvanizing. Second, the zinc layer blocks things. It forms a physical shield. This shield stops water. It stops oxygen. It stops other bad things. These things cannot reach the steel. Both methods protect steel for a long time. They stop rust.

Advantages Over Hot-Dip Galvanizing

Zinc-Rich Cold Galvanizing Paint has many good points. Hot-dip galvanizing dips steel in melted zinc. This is hard for big things. It is also hard for things already built. Cold galvanizing paint goes on at the site. Workers can use a brush. They can use a roller. They can use a spray gun. This works for big bridges. It works for machines already put together. It also fixes damaged hot-dip surfaces easily. If hot-dip coating gets scratched, this paint can fix it. It costs less for some jobs. You do not need to move big items. You do not need to send them to a galvanizing plant. A good paint maker in Pakistan can help. This paint is flexible. It works for many industrial needs. It is often the best zinc paint in Pakistan. It is good for touch-ups. It is good for field work.

Benefits of Zinc-Rich Cold Galvanizing Paint for Pakistani Industries

Extended Asset Lifespan

Zinc-Rich Cold Galvanizing Paint makes steel last longer. It helps structures. It helps machines. It helps equipment. The paint makes a strong layer. This layer stops rust. Industries do not replace things often. They save money. For example, factory steel lasts longer. Power towers stay strong for years. This long life keeps things working. It protects important investments.

Cost-Effectiveness and Maintenance

Pakistani industries save money with this paint. Less upkeep helps save money. The paint stops rust. This means fewer fixes. It means less repainting. Longer life means less spending. Companies buy less new gear. This helps with money plans. It frees up money for other needs. Good protection saves money over time.

Ease of Application and Repair

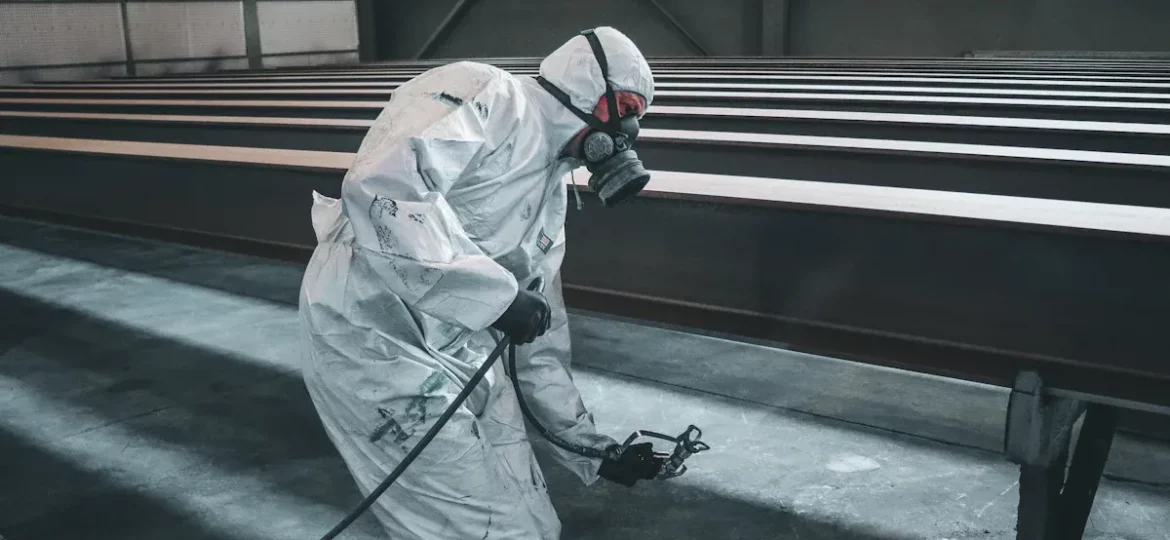

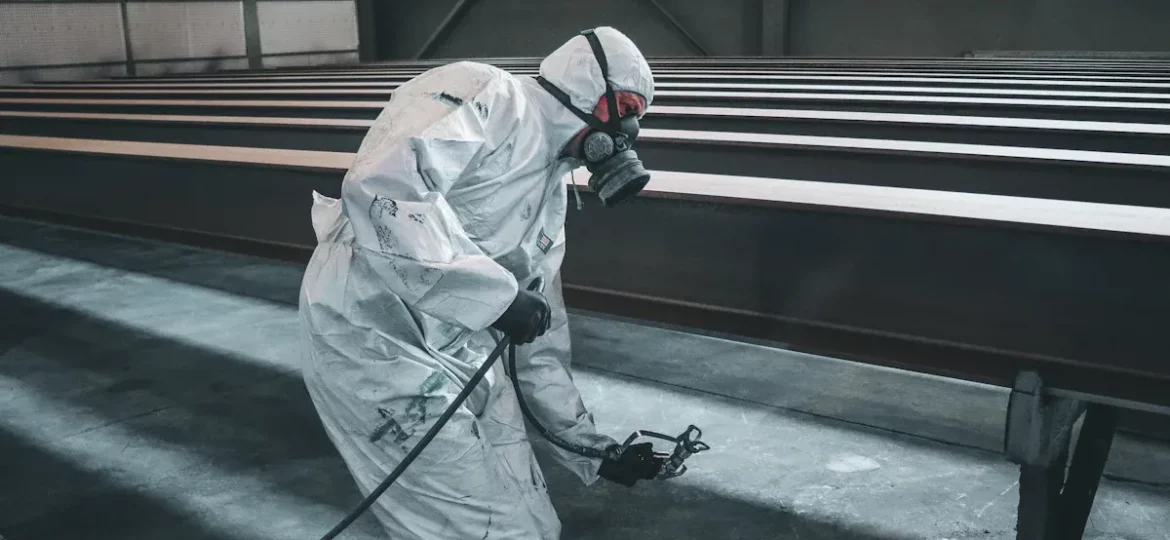

Putting on Zinc-Rich Cold Galvanizing Paint is easy. Workers can paint it on site. They use brushes. They use rollers. They use spray guns. No need to take apart big things. No need to move them to a plant. This saves time. It stops work delays. Small fixes are easy. If scratched, workers repaint it fast. This keeps protection going. This ease helps with upkeep. A good Galvanized Zinc Paint Manufacturer in Pakistan can help.

Versatility Across Sectors

This paint works in many places. Many industries in Pakistan use it.

- Manufacturing: Factories protect steel frames. They protect production lines. They protect storage tanks.

- Power Generation: Power plants use it on towers. They use it on substations. They use it on equipment.

- Oil and Gas: Pipelines get protection. Storage areas get protection. Offshore platforms get protection.

- Infrastructure: Bridges last longer. Train tracks last longer. Port areas last longer.

- Marine Environments: Ships resist salt. Docks resist salt. Coastal things resist salt. It works for many different needs.

Environmental Considerations

Zinc-Rich Cold Galvanizing Paint helps the environment. It means less new steel is needed. This saves raw materials. It uses less energy to make steel. The paint lasts long. This means less waste. It means less harm from upkeep. Some paints have low VOCs. This makes air cleaner when painting. Industries can meet green rules. Products like ZRC Paint Cold Galvanizing Compound follow these rules. It is a good choice for green growth. Many call it the Best zinc paint in Pakistan.

How to Use This Paint in Pakistan

Getting the Surface Ready

Getting the surface ready is key. It helps the paint stick. Workers must clean the steel. They remove rust and old paint. They also remove dirt. Sandblasting works best. It makes the surface rough. This helps the paint bond. Brushing can remove loose rust. Clean steel helps the paint protect.

How to Put on the Paint

Putting on paint correctly helps. It gives good protection. Use a brush for small spots. Use a roller for small spots. Spraying works for big areas. Paint it on smoothly. Make the coat even. The right thickness is important. It gives enough zinc. This protects for a long time. Follow the instructions. This gets the best results.

Drying in Pakistan’s Weather

Pakistan’s weather changes. It can be hot. Humidity also changes. This affects drying time. High humidity slows drying. Hot weather speeds it up. Workers should check the forecast. They change their work plans. Good airflow helps paint dry. It helps it harden fully. This makes the layer strong.

Checking the Work

After painting, check it. Workers check the thickness. They use special tools. The paint must meet standards. They check if it sticks well. It should not peel. It should not chip. Look for missed spots. Look for uneven areas. Good checks mean full protection.

Where to Buy It in Pakistan

Many products are in Pakistan. Marjan Polymer has ZRC Paint. Saifypaints.pk has Zinc Rich Film. They also have ZRC Zinc Rich Compound. Galva Brite is another choice. You can find spray on Daraz.pk. It is 97% pure zinc. Bright Zinc Galvanize is sold. CRC Zinc is sold. Scotch® Zinc Spray 1617 is sold. A good paint maker can help.

Real-World Uses and Stories

Good Results in Factories

Think about a textile factory. It is in Faisalabad. Its steel beams rusted a lot. Air had much water. Chemicals from dyeing made rust fast. The factory used regular paints. These paints did not work well. They needed new paint often. This stopped work. The factory then used a zinc coating. This coating kept the steel safe. It stopped the rust. The steel parts are now strong. The factory saved money. It also kept working. This shows the paint works well. It works in tough factory places.

Keeping Big Projects Safe

Pakistan’s big projects also gain. A large bridge near Karachi needed help. Salt air from the sea caused bad rust. Engineers picked a cold zinc paint. They put it on the bridge’s steel parts. This kept the steel safe. It fought the harsh sea air. Power towers in Punjab face bad weather. These towers got the same paint. The paint made them last longer. It cut down on repairs. This keeps power flowing. Oil and gas pipes also use this. It stops leaks and breaks.

How It Compares

This special paint works better. It beats old ways. For example, near the coast. Regular paints just block rust. They scratch easily. Then rust starts fast. Hot-dip galvanizing works well. But it is hard for big, old things. You have to take them apart. Zinc-Rich Cold Galvanizing Paint blocks and protects. It is easy to put on. It gives strong, long-term defense. This makes it a smart choice. It helps many Pakistan industries.

Stopping rust is key. It helps steel in Pakistan. Zinc-Rich Cold Galvanizing Paint is a strong answer. It protects in two ways. It uses cathodic and barrier protection. This paint saves money. It is easy to put on. Companies can use it where they are. This new way is a smart buy. It helps Pakistani businesses. It makes things last longer. It lowers costs. It also helps growth. Business leaders should think about this. It protects their steel. A good paint maker in Pakistan can help. They offer the best zinc paint. ZRC Paint Cold Galvanizing Compound is one exa