You must control things exactly to get good results in bioengineering. An advanced Fermentation Tank helps you control temperature, pH, and oxygen very well. You can use special sensors and systems to keep these things steady. This setup lets you make bioproducts faster and easier. When you control these important parts, you help microorganisms grow their best. This means you get more products and better quality each time.

Fermentation in Bioengineering

Central Role

You play a key part in bioengineering when you use fermentation. This process lets you turn raw materials into valuable products. You can use bacteria, yeast, or fungi to make things like medicine, food, and fuel. When you guide microbial growth, you help these tiny organisms work together to create new bio solutions.

Fermentation gives you a way to control how fast and how well these organisms grow. You can adjust the environment to fit the needs of each type of microbe. This control helps you get the best results from your work. In industrial fermentation, you often need to make large amounts of product. A Fermentation Tank helps you do this by giving you a safe and steady place for the microbes to grow.

Tip: When you understand how fermentation works, you can solve many problems in science and industry.

Impact of Tank Quality

The quality of your tank matters a lot. If you use a high-quality Fermentation Tank, you can keep the environment just right for your microbes. You can control temperature, pH, and oxygen levels. This control helps you avoid problems like contamination or slow growth.

A good tank lets you watch the process in real time. You can see if something goes wrong and fix it quickly. This means you waste less time and money. You also get more product that meets your standards. Poor tanks can lead to failed batches or unsafe products. When you choose the right equipment, you set yourself up for success in industrial fermentation and bio solutions.

Fermentation Tank Features

Automation

Automation in a Fermentation Tank makes your job easier. Automated systems control temperature, pH, and oxygen for you. You set the values you want, and the tank keeps them steady. This saves you time because you do not have to check things by hand. You can focus on planning your next steps. Automation helps stop mistakes and keeps your batch safe. The tank can fix problems fast if something changes. In big fermentation jobs, automation lets you handle more work with less worry.

Note: Automated tanks let you react quickly to changes. This keeps your microbes safe and helps you make better bio solutions.

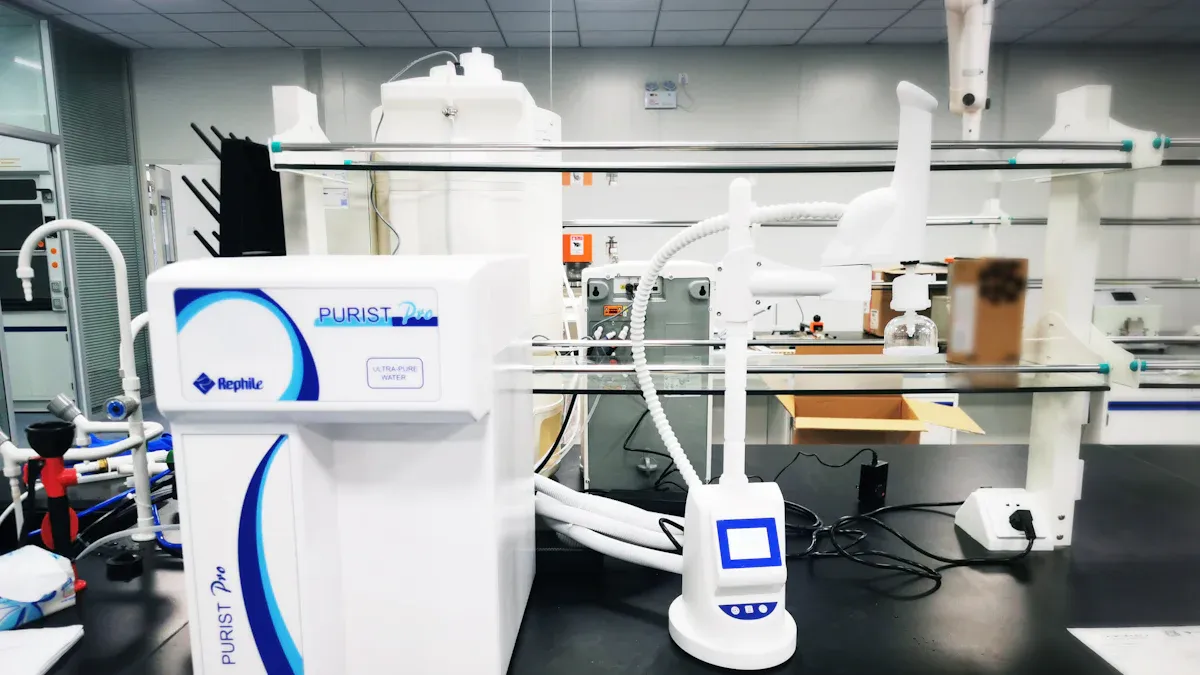

Monitoring

You always need to know what is happening inside your Fermentation Tank. Advanced sensors show you real-time data for temperature, pH, and oxygen. You can see these numbers on a screen and act fast if there is a problem. Monitoring helps you find issues early, so you do not lose a batch. You can watch trends and learn how your microbes act. This helps you make your process better and get the same results each time. When you monitor your tank well, you help your microbes grow strong and make good bio solutions.

- Real-time monitoring helps you:

- Find problems before they get worse

- Change settings for better results

- Keep your process safe and steady

Sterility

You need to keep your Fermentation Tank clean to protect your microbes. Sterility stops bad germs from getting in and ruining your batch. Advanced tanks use special designs and cleaning systems to stay pure. You can use steam or chemicals to clean the tank between uses. This keeps your microbes healthy and your products safe. Sterile tanks help you avoid contamination, which saves time and money. In big fermentation jobs, sterility is very important for making good bio solutions.

Tip: Always check your cleaning system before you start a new batch. Clean tanks help you get better results.

Scalability

A scalable Fermentation Tank lets you grow your process. Scalability means you can start small and make more when you need to. Advanced tanks let you change size or add new parts for different microbes and jobs. You can set up the tank for bacteria, yeast, or fungi. This helps you try new ideas and make more product when you are ready. Scalability helps you grow in industrial fermentation and meet the need for bio solutions.

- Customizable tanks let you:

- Switch between different microbes

- Change for new products or jobs

- Make more product without losing quality

Benefits

Yield

You want to get the most product from your process. An advanced Fermentation Tank helps you do this by giving you control over every part of microbial growth. You set the temperature, pH, and oxygen levels exactly where your microbes need them. When you keep these settings steady, your microbes grow faster and stronger. You see bigger yields because your microbes work at their best.

Tip: Real-time adjustments let you fix problems right away. You do not lose batches, and you get more product each time.

You use these tanks in industrial fermentation to make large amounts of bio solutions. You can trust your results because the tank keeps everything stable. You do not waste raw materials, and you get more out of every batch.

Quality

You care about the quality of your products. Advanced tanks help you keep your standards high. You watch every change inside the tank with sensors and control systems. If something goes wrong, you see it fast and fix it before it hurts your batch. You get products that look and work the same every time.

You avoid contamination because the tank stays clean and sterile. Your microbes stay healthy, and your bio solutions meet safety rules. You build trust with your customers because your products always meet their needs.

- Benefits of advanced tanks for quality:

- Consistent results

- Safe and pure products

- Fast response to changes

Cost

You want to save money while making good products. Advanced tanks help you do this by cutting down on waste and mistakes. You do not need to throw away bad batches because you catch problems early. You use less energy and fewer raw materials because the tank works efficiently.

You spend less time fixing errors and more time making products. Automation lets you run bigger jobs without hiring more people. You see lower costs in every part of your process, from start to finish.

Note: Investing in an advanced Fermentation Tank pays off over time. You get better yield, higher quality, and lower costs with every batch.

Applications

Pharmaceuticals

A Fermentation Tank helps make important medicines. Drug companies use fermentation to make antibiotics, vaccines, and insulin. Inside the tank, bacteria or yeast grow. These microbes help create safe medicines. You control temperature, pH, and oxygen. This keeps the microbes growing well. You get the same results every time. Each batch meets strict quality rules. This protects patients and keeps medicine safe.

Did you know? Penicillin is an antibiotic made from fungus in a Fermentation Tank.

Enzymes

Fermentation Tanks also help make enzymes. Enzymes are used in food, cleaning, and clothes. Special bacteria or fungi make these proteins. Advanced tanks keep the environment just right. This helps microbes make more enzymes faster. You can use different microbes for new enzymes. This helps many industries with good bio solutions.

- Using Fermentation Tanks for enzymes gives you:

- Faster production

- Higher purity

- Easy scaling

Biofuels

Fermentation Tanks help make biofuels for the planet. Yeast or bacteria turn plant sugars into fuel. You can make ethanol or biodiesel this way. Industrial fermentation makes lots of clean energy. You control each step and waste less. You get more fuel from every batch. Bio solutions from microbes help green energy and cut pollution.

Tip: Advanced Fermentation Tanks let you try new microbes and improve your biofuel process.

Advanced vs. Basic Tanks

Limitations

Basic Fermentation Tanks have many limits. They do not control temperature, pH, or oxygen well. You cannot change these settings easily. Microbes may not grow as they should. Sometimes, growth is uneven or very slow. Basic tanks do not show you what is happening inside. You miss early problems and lose batches. It is hard to make more product for big jobs. You cannot switch between different microbes or bio solutions.

- Basic tanks often:

- Do not have advanced sensors

- Do not use automation

- Have trouble staying sterile

Risks

Using basic Fermentation Tanks can be risky. Cleaning is hard, so contamination can ruin your batch. You cannot fix changes in the tank quickly. Microbes may stop growing or grow slowly. Failed batches waste time and money. These risks get bigger with larger tanks. You may not meet safety rules or quality needs. Your bio solutions may not work right.

Alert: Bad tank design can make unsafe products and waste resources.

Value

Advanced Fermentation Tanks give you strong value. Stainless steel mix tanks keep things clean and steady. You control every part of how microbes grow. Automation and sensors help you watch your process. You fix problems fast and keep bio solutions safe. Advanced tanks let you make more product for big jobs. You can switch between microbes and products easily. You get more yield, better quality, and lower costs.

- Advanced tanks give you:

- Good microbial growth every time

- Safe and pure bio solutions

- Flexibility for new projects

Tip: Buying advanced Fermentation Tanks helps you do well in bioengineering and stay ahead.

A Fermentation Tank helps you control how microbes grow. Advanced features help you get better results in big jobs. You make more product, keep things safe, and trust your bio solutions.

- Real-time monitoring helps you make each batch better.

- Automation saves you time and money.

- Sterility keeps your process safe from bad germs.

Buying advanced Fermentation Tanks helps you do well in bioengineering. You set yourself up for success in the future.