Steel rust presents significant challenges in Pakistan, leading to substantial economic losses and structural damage to infrastructure. Traditional steel protection methods, such as hot-dip galvanization, often fall short in providing adequate, long-term defense. Pakistan urgently requires superior, durable solutions to safeguard its steel assets. This blog explores innovative rust prevention strategies, specifically focusing on how Advanced Anti-Corrosion Formulas can effectively combat Pakistan’s harsh environmental conditions. By embracing cutting-edge scientific advancements, Pakistan can ensure its steel structures are protected for decades to come.

Pakistan’s Rust Problems

Steel buildings in Pakistan face many dangers. The country’s weather makes steel rust faster. Old buildings also have problems. We need better ways to protect steel.

Wet Air and Salt

Pakistan’s coast has very wet air. This wetness makes steel rust quickly. Air from the Arabian Sea also carries salt. This salt lands on steel. Salt helps rust form faster. Buildings near Karachi rust a lot. They need strong rust protection.

Dirty Air and Acid Rain

Factories in Pakistan make the air dirty. They release bad gases. These gases mix with water in the air. This makes acid rain. Acid rain eats away at steel. It removes the steel’s protective layer. This makes the steel rust more easily. Cities like Lahore have more rust. This is because of dirty air.

Old Buildings

Many of Pakistan’s structures are old. Bridges, buildings, and pipes are decades old. Their old coatings do not work well. These coatings wear out. Then, the steel underneath rusts easily. Fixing old buildings costs a lot. So, new and better protection is very important. This helps Pakistan grow.

Types of Advanced Anti-Corrosion Formulas

New ways to fight rust are much better. They protect steel more than old ways. These special formulas work in different ways. Some make strong walls. Others fix damage by themselves. Some even give up to save the steel. These new formulas make steel last longer. They also mean fewer fixes are needed.

Smart Polymer Coatings

Smart polymer coatings are like a shield. They use special plastics. These plastics stick well to metal. The coatings make a strong layer. This layer stops water. It also stops oxygen. Harmful chemicals cannot reach the steel. Regular paints also make a wall. But smart coatings have tiny bits. Or they have special chemicals. These make the wall stronger. They also stop scratches. They resist wear. Some smart coatings can even change. They might get harder. This happens in certain conditions. This gives active protection.

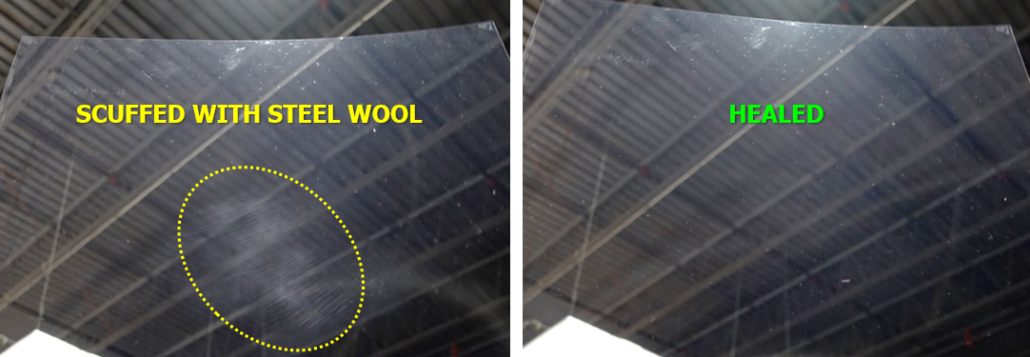

Self-Healing Systems

Self-healing systems are very new. They can fix themselves. Imagine a small scratch. It is on a coating. In these systems, tiny capsules open. They are inside the coating. They let out a healing liquid. This liquid fills the scratch. It then gets hard. This fixes the protective layer. This stops rust from starting. It also makes the coating last longer. This active fix works better. It is better than just repainting.

Nanotechnology Solutions

Nanotechnology uses tiny particles. They protect steel. These nanoparticles are very small. They are smaller than a human hair. When put in coatings, they fill small gaps. This makes the coating thicker. It lets less through. It makes a stronger wall. This wall stops rust. Some nanoparticles absorb bad UV light. Zinc oxide and titanium dioxide do this. This keeps the coating from breaking. Other nanoparticles stop rust. They let out chemicals. These chemicals protect the steel. This stops rust before it spreads. Special surfaces also push water away. This keeps water off the steel.

Eco-Friendly Options

The world needs greener ways. Eco-friendly rust protection uses safer materials. These materials are better for nature. They include plant-based rust stoppers. They come from plants. They break down easily. Water-based coatings use fewer harsh liquids. These liquids make bad fumes. Films that break down offer short-term protection. They protect steel when moved. Or when stored. These films dissolve safely later. Scientists also make new mixes. These mixes protect well. They do not use bad chemicals. This helps steel and the Earth.

Smart Coatings and Self-Healing Materials

These special coatings do more. They don’t just sit there. They react to damage. They react to changes. They give new protection. This is for steel buildings.

Intelligent Polymer Coatings

Intelligent polymer coatings are smart shields. They protect steel. They use special plastics. These make a strong wall. This wall stops water. It stops oxygen too. This keeps them from the metal. Some coatings have tiny sensors. These find early rust. They might change color. Or they send a signal. This tells workers about a problem. It happens before it gets bad. Other smart coatings can change. They might get harder. This happens in bad weather. This makes them strong. They resist scratches. They resist wear. These coatings mix things. They mix organic polymers. They mix inorganic particles. This makes a strong layer. It can also react.

Microcapsule-Based Self-Healing

Microcapsule-based self-healing is new. It is very clever. Think of a coating. It can fix itself. These coatings have tiny capsules. There are millions of them. Each capsule holds a liquid. This liquid heals things. A crack damages the coating. Or a scratch does. These capsules break open. They let out the liquid. It goes into the damaged spot. The liquid then gets hard. It fills the crack. This seals the surface. It stops rust from starting. This happens at the damaged spot. This self-repair makes the coating last. It also means fewer repairs. This saves time. It saves money.

Bio-Inspired Repair

Nature gives us ideas. It inspires new tech. Bio-inspired repair copies nature. It copies how living things heal. Some coatings use ideas. They come from human skin. They can find damage. They start to fix it. Scientists make materials. These can grow. Or they can fix themselves. These materials might use special polymers. They react to light. Or to moisture. They make new connections. This mends breaks. Other systems get ideas from plants. They can seal wounds. They stop infection. These nature-inspired ways are good. They last a long time. They help save steel. They are the future. They are anti-corrosion tech.

Tiny Tech for Better Protection

Nanotechnology uses very small things. These things are super tiny. They make coatings better. Coatings stick more. They protect steel in new ways. These tiny things help a lot.

Tiny Particle Coatings

Tiny particle coatings use small bits. These bits are smaller than hair. They fill small holes in coatings. This makes the coating thicker. It makes a strong wall. This wall stops water. It stops air too. They cannot reach the steel. Some tiny bits soak up bad UV light. Zinc oxide and titanium dioxide do this. This keeps the coating safe. Other tiny bits let out chemicals. These chemicals stop rust. This protects the steel more.

Graphene and CNTs

Graphene and Carbon Nanotubes (CNTs) are special. They are nanomaterials. Graphene is one layer of carbon. CNTs are tiny carbon tubes. Both are very strong. They are also very light. They make coatings tougher. They make a great wall. This wall stops rust stuff. It stops cracks too. These materials also help coatings move power. This helps some rust systems.

Tiny Patterned Surfaces

Scientists can change steel surfaces. They do this at a tiny level. This makes tiny patterned surfaces. These surfaces have special traits. Some surfaces push water away. They are super water-repellent. Water rolls off them. This keeps steel dry. It stops rust. Other tiny patterned surfaces clean themselves. This means less work. These surfaces keep steel safe.

Eco-Friendly Corrosion Inhibitors

We need safer ways. We need to protect steel. These new ways are better. They help the environment. They use fewer bad chemicals. They also make less pollution. These ideas keep steel safe. They also protect our Earth.

Green Corrosion Inhibitors

Green rust stoppers come from nature. They are less toxic. Old chemicals were worse. Many come from plants. Plant extracts stop rust. They work on mild steel. These extracts make a thin layer. It goes on the metal. This layer protects steel. It stops water and air. Scientists use HMBA. It is a compound. It stops rust well. It is also better for nature. Special treatments use lignin. Lignin comes from wood. It makes a shield. PDMS is another material. It makes surfaces shed water. This keeps steel dry.

Water-Based Coatings

Old coatings use strong liquids. These liquids make bad fumes. Water-based coatings use water. It is their main liquid. This means fewer bad chemicals. They are safer for people. They are better for air. These coatings still protect well. They make a wall against rust. They are a good choice. They help stop pollution.

Biodegradable Films

Biodegradable films protect for a short time. They help steel when moved. Or when stored. These films break down. They do it naturally. They leave no bad waste. They protect steel from wetness. They protect from air. The film goes away. This happens when steel is used. This means less hard cleaning. It also means less trash. These films are a good choice. They protect steel. They do not harm nature. They are smart for short needs.

How Pakistan’s Industries Can Use These Formulas

New rust-fighting formulas help many areas in Pakistan. They keep important things safe. They make things last longer. They also cut down on repair costs.

Big Building Projects

Pakistan’s big building projects can really use these formulas. Bridges, roads, and public buildings need strong protection. For example, new bridges can use smart polymer coatings. These coatings fight bad weather. They also stand up to dirty air. Self-healing materials make concrete last longer. They stop rebar from rusting. This is key for roads and bridges near the sea. These places have wet air and salt. Using these formulas makes things safe. It also means fewer fixes are needed.

Oil and Gas Sites

Pakistan’s oil and gas sites work in tough places. Pipes, tanks, and sea platforms face bad rust. Nanotechnology solutions give great protection. They fight strong chemicals and saltwater. Coatings with graphene can protect pipes. They stop leaks and breaks. Green rust stoppers can protect the inside of tanks. They do this without hurting nature. These uses make work safer. They also lower harm to the environment.

Sea Buildings

Sea buildings in Pakistan, like ports, always fight saltwater rust. This place is very harsh. New rust-fighting formulas are a must here. Repair systems like nature’s can protect parts underwater. They fix small damages. This stops rust from spreading. Smart polymer coatings can check how strong things are. They give early warnings of problems. This way of acting saves a lot on repairs. It also makes sea assets last longer.

Factory Machines

Many factories in Pakistan use big machines. This includes plants that make things and power stations. Factory machines often work in air that causes rust. Nanoparticle coatings can protect key machine parts. They fight wear and chemical damage. Water-based coatings are a safer choice for painting machines. They mean workers breathe fewer bad fumes. Films that break down can protect new machines. This is for when they are moved or stored. This makes sure they arrive in great shape. These fixes make machines more reliable. They also mean less time spent on repairs.

How to Use and Check

Companies must put on special rust-fighting paints the right way. They also need to check if they work. This makes steel last a long time. Doing it right makes sure they work well.

Getting Ready and Putting On

First, clean the steel very well. This removes rust and dirt. It also takes off old paint. This helps the new paint stick. If not clean, paint will fail fast. Next, put on a first coat. This helps the main paint stick. Then, put on the special paint. Some paints need spraying. Others can be brushed on. Always follow the directions. This is very important.

Checking the Work

Workers check the paint job. They make sure it meets standards. They measure how thick the paint is. This shows if it will protect. They check if the paint sticks well. They look for bad spots. This stops early rust. Good checks save money later. Special tools help them check.

Watching Over Time

We watch how the paint works. We look for damage. Special tests check the paint. They do not harm the steel. Sensors watch the weather. They check for wetness or heat. This helps us fix things early. This makes steel last longer. It keeps it safe.

Money Saved

These special paints cost more at first. But they save money later. They make steel last longer. This means fewer fixes. Companies save money on upkeep. They also avoid shutdowns. These paints stop big problems. They are better for the Earth too. They use fewer bad chemicals. They make less trash.

Advanced anti-rust formulas are very important. They keep Pakistan’s steel safe. These new ways help a lot. They save money. They make things safer. They are also good for nature. They protect steel better. They fight Pakistan’s tough weather. They also fight factory dangers. Companies, schools, and the government must work together. This will help create new ideas. It will help use them everywhere. Pakistan can be a leader. It can protect steel in a good way. This keeps its future safe.