Prepreg Epoxy Resin

Advanced Composite Resin Solution

Prepreg Epoxy Resin by Resoltech Spain

Product Introduction

Prepreg Epoxy Resin by Resoltech Spain is a premium, high-performance resin designed specifically for prepreg applications in advanced composite manufacturing. This state-of-the-art epoxy resin is engineered to offer superior mechanical properties, thermal stability, and exceptional adhesion to reinforcement fibers. Ideal for aerospace, automotive, marine, and renewable energy industries, this resin ensures high-quality, durable, and lightweight composite materials.

Key Features

Superior Mechanical Properties

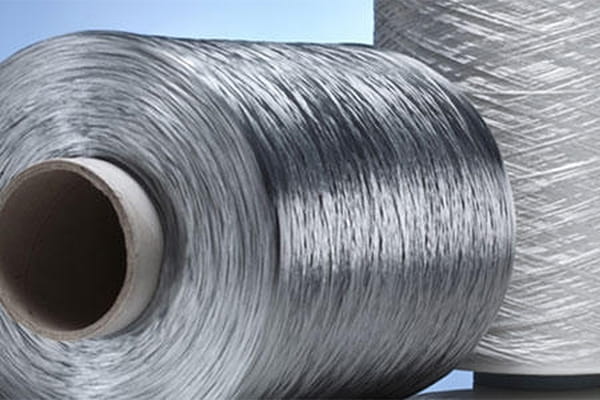

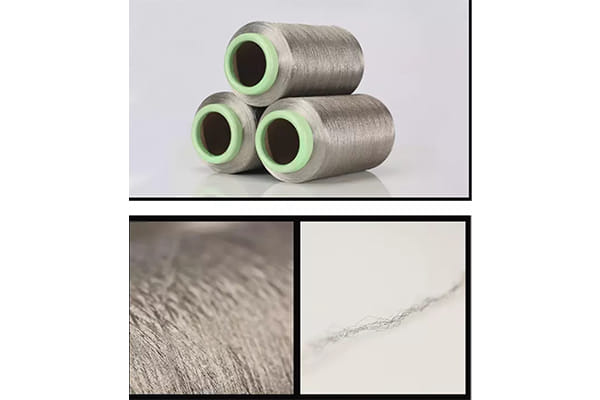

- High Adhesion: Provides strong bonding to various reinforcement fibers, including carbon, glass, and natural fibers.

- Durability: Ensures long-lasting performance with excellent resistance to mechanical stress and environmental factors.

Thermal Stability

- High Temperature Resistance: Maintains integrity and performance at elevated temperatures, making it suitable for high-temperature applications.

- Consistent Performance: Offers reliable performance under thermal cycling conditions.

Versatile Applications

- Multi-Surface Compatibility: Suitable for bonding a wide range of reinforcement fibers, enhancing its versatility in composite manufacturing.

- Chemical Resistance: Resists exposure to various chemicals and solvents, ensuring reliable performance in harsh conditions.

Easy Application

- Prepreg Process: Formulated for easy impregnation of fibers, ensuring uniform resin distribution and optimal fiber wet-out.

- Curing Options: Can be cured at elevated temperatures to achieve desired mechanical properties.

Specifications Table

| Feature | Specification |

|---|---|

| Manufacturer | Resoltech Spain |

| Grade | Prepreg Epoxy Resin |

| Composition | Two-part epoxy |

| Mix Ratio | 100:30 (resin) |

| Working Time | 60 minutes |

| Cure Time | 2 hours at 120°C (248°F) |

| Shear Strength | 5,000 psi |

| Temperature Resistance | Up to 180°C (356°F) |

| Chemical Resistance | Excellent |

| Color | Clear to amber |

| Packaging | Available in various sizes |

Types of Epoxy Resins

Standard Epoxy Resin

- Description: Provides reliable bonding for general-purpose applications.

- Benefits: Offers a balance of strength, durability, and versatility.

High-Temperature Epoxy Resin

- Description: Specifically formulated for high-temperature environments.

- Benefits: Maintains bond strength and integrity under extreme heat.

Chemical-Resistant Epoxy Resin

- Description: Provides enhanced resistance to chemicals and solvents.

- Benefits: Ensures long-lasting performance in chemically aggressive environments.

Applications

Aerospace and Defense

- Usage: Ideal for manufacturing high-performance aerospace components.

- Benefits: Ensures lightweight, durable, and high-strength composite materials.

Automotive and Transportation

- Usage: Suitable for producing automotive parts and transportation components.

- Benefits: Enhances the durability and performance of vehicles and transportation systems.

Marine and Offshore

- Usage: Used in the production of marine structures and offshore components.

- Benefits: Provides excellent resistance to marine and harsh environmental conditions.

Renewable Energy

- Usage: Ideal for manufacturing wind turbine blades and other renewable energy components.

- Benefits: Ensures strong, durable, and lightweight composites for renewable energy applications.