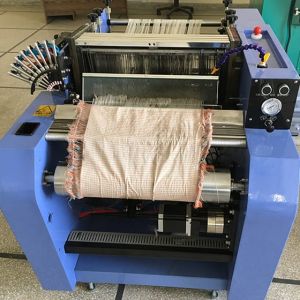

Yarn Winding Machine

High-Efficiency Yarn Winding Machine

Advanced Technology for Textile Manufacturing

Introduction

The Yarn Winding Machine is a high-efficiency device designed to wind various types of yarns into precise and uniform packages. This advanced machine is essential for textile manufacturing processes, ensuring high-quality yarn preparation for subsequent weaving or knitting operations. Its robust construction and innovative features make it a valuable asset for textile manufacturers seeking reliable and efficient winding solutions.

Key Features

- Versatile Yarn Compatibility: Suitable for winding elastic yarn, cotton yarn, silk, polyester, polyester filament, nylon, DTY, FDY, viscose yarn, and more.

- High Winding Speed: Capable of winding speeds from 0 to 1200 meters per minute, adjustable based on yarn quality and feed package.

- Adjustable Package Shape: Supports square end cheese cone and taper end cheese cone with a taper angle range of 0 to 5°.

- Multiple Spindles: Equipped with up to 6 spindles per machine, allowing for efficient winding operations.

- Precise Taper Angle: Features a taper angle of Oct 35° CAD for consistent package formation.

- Variable Traverse Length: Traverse length ranges from 25mm to 250mm, accommodating various package sizes.

- Robust Motor System: Includes winding motor (180W), transverse motor (50W), gate tension motor (5W), overfeed motor (60W), and oiling motor (5W) for optimal performance.

- Total Power: 300W total power per spindle, ensuring efficient and powerful operation.

Types

- Standard Model SR1: Ideal for general yarn winding applications, offering reliable and efficient performance.

- High-Capacity Model: Designed for large-scale production, providing enhanced capacity and speed.

- Customized Model: Tailored for specific yarn types and winding requirements, ensuring optimal performance and efficiency.

Applications

- Textile Manufacturing: Essential for preparing yarns for weaving or knitting, ensuring uniform and high-quality packages.

- Fashion and Apparel: Suitable for winding yarns used in clothing and fashion accessories.

- Home Textiles: Ideal for preparing yarns for home textile products like bed linens, curtains, and upholstery.

- Technical Textiles: Used in the production of technical textiles requiring precise yarn winding.

- Industrial Textiles: Suitable for winding yarns used in industrial textile applications.

Specifications

| Specification | Details |

|---|---|

| Yarn Type | Elastic yarn, cotton yarn, silk, polyester, polyester filament, nylon, DTY, FDY, viscose yarn |

| Number of Spindles | 6 |

| Winding Speed | 0-1200 m/min |

| Shape of Package | Square end cheese cone, taper end cheese cone |

| Range of Taper Angle | 0 – 5° |

| Traverse Length | 25mm to 250mm |

| Motor Power | Winding motor 180W, transverse motor 50W, gate tension motor 5W, overfeed motor 60W, oiling motor 5W |

| Total Power | 300W per spindle |

| Electricity Device | 3-phase 220V 50 Hz |

| Package Size | Maximum roller width 250mm, 8 inches’ square end roller, 6 inches’ taper end roller, 8 inches’ taper end roller |

Accessories

- Replacement Parts: High-quality spare parts for continuous operation and minimal downtime.

- Maintenance Kits: Includes essential tools and components for routine maintenance.

- Tension Control Devices: Additional devices for precise tension management.

- Cleaning Equipment: Tools and materials for maintaining the winding machine and ensuring optimal performance.

Installation and Training

Comprehensive installation guidelines are provided to ensure proper setup and operation. Training sessions can be arranged upon request to educate users on the correct usage, maintenance, and troubleshooting of the Yarn Winding Machine. This ensures maximum efficiency and longevity of the equipment.

Warranty Information

- Standard Warranty: 12 months limited warranty covering parts and after-sales services, except for consumable parts and damages caused by user errors, electrical failures, fires, or natural disasters.