You see fast changes in Zinc-Based Metal Protection now. New technologies help you stop metal from rust and harm. You save money and help the earth by using these new solutions. Many industries now look for strong, eco-friendly ways to keep metal safe.

Latest Innovations

Advanced Coatings

There are new coatings that keep metal safe for longer. These coatings have special mixes to stop rust and harm. Some coatings last a long time and work in hard places. Many companies use these coatings to save money and keep metal strong.

- These coatings protect metal from water and chemicals.

- You do not need to fix metal as often.

- These coatings use fewer bad chemicals, so they help the earth.

Tip: Pick advanced coatings if you want strong safety for bridges, cars, or machines.

Hybrid and Composite Solutions

You can use hybrid and composite solutions for Zinc-Based Metal Protection. These solutions mix zinc with other things like polymers or ceramics. You get the good parts of each material. Zinc stops rust, and polymers make metal strong and bendy.

| Material | Benefit | Common Use |

|---|---|---|

| Zinc | Stops corrosion | Steel beams |

| Polymer | Adds flexibility | Pipes |

| Ceramic | Resists heat | Engine parts |

You see these solutions where metal gets hot, wet, or used a lot. Metal parts last longer with these solutions.

Nano and Smart Technologies

Now, nano and smart technologies help protect metal. Nano coatings use tiny bits to cover metal better. These tiny bits fill small spaces and make a strong shield. Smart coatings can find damage and fix themselves.

- Nano coatings keep metal safe from rust and scratches.

- Smart coatings change color if they find damage.

- You get a warning when your metal needs care.

Note: Nano and smart technologies help you keep metal safe with less work. You can use them in electronics, cars, and buildings.

Protection Mechanisms

Barrier Effect

You get strong protection from zinc coatings because they form a solid barrier on metal surfaces. This barrier keeps water, air, and chemicals away from the steel underneath. When you use zinc coatings, you stop rust from starting. The coating sticks well to the metal, so it does not peel off easily. You also see that zinc coatings resist scratches and wear. This means your metal stays safe even in tough places.

- Zinc coatings block moisture and oxygen.

- You do not need to worry about small scratches because the coating stays strong.

- The barrier effect works best when you need long-lasting protection.

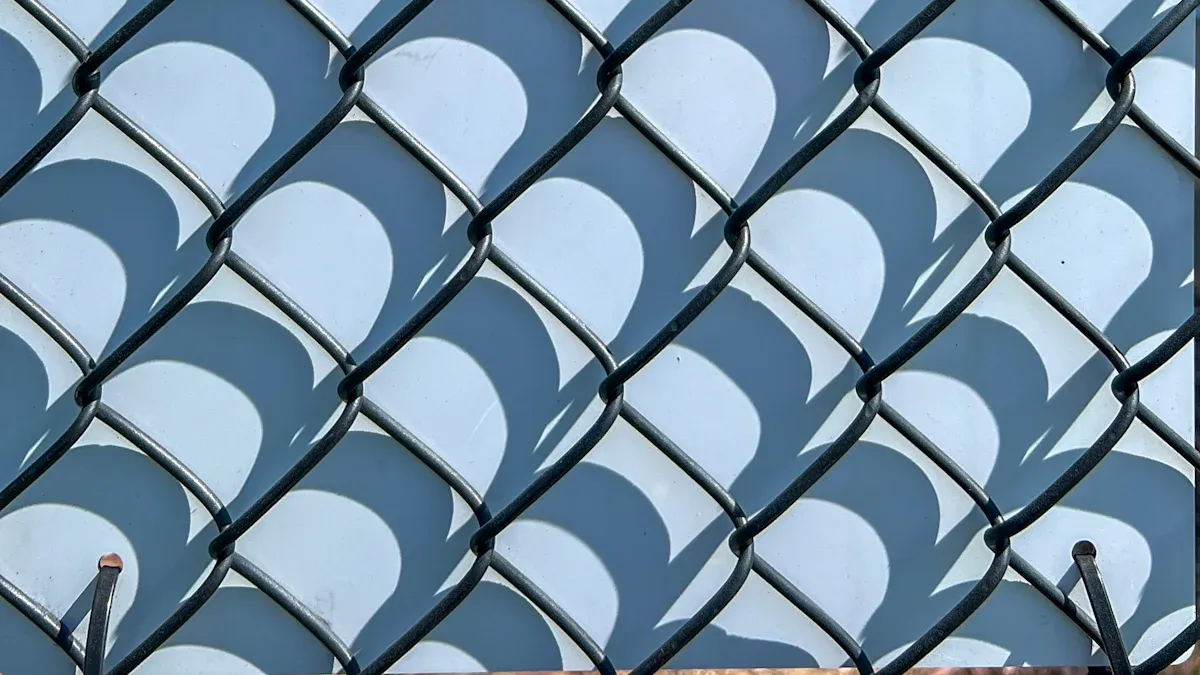

Tip: Use zinc coatings on bridges, fences, and outdoor machines for the best barrier effect.

Cathodic Action

Zinc does more than just cover the metal. It also protects steel through cathodic action. When the coating gets scratched, zinc reacts first instead of the steel. This stops rust from spreading. You can think of zinc as a shield that takes the damage so your steel stays safe.

- Zinc sacrifices itself to protect steel.

- Even if the coating breaks, the metal underneath does not rust right away.

- This action makes Zinc-Based Metal Protection very reliable.

Note: Cathodic action is why zinc coatings work so well for pipes, tanks, and other steel parts that face harsh conditions.

Application Methods

Zinc Plating

You can use zinc plating to protect small metal parts. In this method, you place the metal in a special bath with zinc. An electric current moves zinc onto the metal surface. This thin layer of zinc keeps out moisture and air. You often see zinc plating on nuts, bolts, and car parts. It gives a smooth finish and helps stop rust. If you want a shiny look and basic protection, zinc plating works well.

Tip: Choose zinc plating for tools, fasteners, and small machine parts that need a clean appearance.

Hot-Dip and Cold Galvanizing

Hot-dip galvanizing gives you a thick, tough layer of zinc. You dip the metal into hot, melted zinc. The zinc sticks to the metal and forms a strong shield. This method works best for large items like fences, beams, and outdoor structures. Cold galvanizing uses zinc-rich paint. You brush or spray it onto the metal. It is easy to use for repairs or small jobs, but the layer is thinner than hot-dip.

| Method | Best For | Protection Level |

|---|---|---|

| Hot-Dip | Bridges, poles | High |

| Cold Galvanize | Repairs, touch-ups | Medium |

Advanced Spraying Techniques

You can use advanced spraying techniques for fast and even coverage. Special spray guns apply zinc coatings to metal surfaces. This method works well for large or oddly shaped items. You control the thickness and reach hard spots. Advanced spraying helps you save time and get good results. Many industries use this for Zinc-Based Metal Protection because it covers big areas quickly.

Note: Spraying works best when you need to protect large equipment or structures in a short time.

Sustainability

Low-VOC and Water-Based Options

You can pick low-VOC and water-based coatings to help nature. VOC means volatile organic compounds. These chemicals can make the air dirty and hurt people. Many new zinc coatings have less VOCs now. Water-based coatings use water instead of strong chemicals. This makes the air cleaner and safer for workers.

- Water-based coatings dry quickly and protect metal well.

- Low-VOC coatings follow strict clean air rules.

- You can use these coatings inside factories or near people.

Tip: Choose water-based or low-VOC coatings if you want to keep metal safe and help the planet too.

Recyclable Processes

You help the earth by using recyclable processes in Zinc-Based Metal Protection. Many zinc coatings can be taken off and used again. Factories collect extra zinc and use it for new coatings. This saves resources and makes less waste.

- Recyclable coatings mean you need fewer new materials.

- You make less trash by recycling old coatings.

- Many companies use recyclable ways to meet green goals.

Note: Recycling zinc helps the earth and saves money on materials.

Benefits of Zinc-Based Metal Protection

Durability

You want your metal structures to last a long time. Zinc-Based Metal Protection gives you strong and lasting results. Zinc coatings form a tough shield that stands up to rain, salt, and chemicals. You see less rust and fewer repairs. Many bridges, ships, and factories use zinc coatings because they keep working for years. You can trust zinc to protect steel in harsh places like the ocean or busy roads.

Tip: Choose zinc coatings if you need metal to stay strong in tough weather or heavy use.

Cost Efficiency

You save money when you use zinc coatings. These coatings last longer than regular paint. You do not need to repaint or fix metal as often. This means you spend less on labor and materials over time. Many companies pick zinc because it lowers costs for big projects. You get more value from your investment.

| Benefit | Zinc Coating | Regular Paint |

|---|---|---|

| Lasts longer | ✅ | ❌ |

| Fewer repairs | ✅ | ❌ |

| Saves money | ✅ | ❌ |

Environmental Impact

You help the planet when you use Zinc-Based Metal Protection. Zinc coatings often use fewer harmful chemicals than old paints. Many new zinc products are water-based or recyclable. You make less waste and keep the air cleaner. Zinc also helps metal last longer, so you do not need to replace parts as often. This saves resources and energy.

Note: Zinc coatings support green goals in building, shipping, and industry.

Applications

Infrastructure

You see Zinc-Based Metal Protection used in many parts of city life. Bridges, highways, and power towers all need strong protection from rust and weather. When you use zinc coatings on these structures, you help them last longer. You also lower the cost of repairs. Many cities choose zinc coatings for street lights, guardrails, and water pipes. These coatings keep metal safe from rain, snow, and pollution.

Tip: If you work with public projects, pick zinc coatings to make your structures last and save money.

Marine Environments

Saltwater can damage metal very fast. You need extra protection for ships, docks, and oil rigs. Zinc-Based Metal Protection works well in these places. Zinc coatings stop rust from eating away at steel. You see fewer repairs and less downtime. Many boat owners and port managers trust zinc to keep their equipment strong.

- Use zinc coatings for:

- Ship hulls

- Offshore platforms

- Harbor equipment

Industrial Use

Factories and warehouses use a lot of metal. Machines, storage racks, and pipes all face wear and tear. When you use zinc coatings, you protect these parts from chemicals and heavy use. You also keep your equipment running longer. Many industries, like food processing and car making, rely on zinc to keep their operations safe and smooth.

Note: Zinc coatings help you avoid costly breakdowns and keep your business moving.

Comparison with Traditional Methods

Performance

You get better protection with zinc-based coatings than with regular paint. Zinc forms a strong shield that blocks water and air. Paint can chip or peel, but zinc sticks well and lasts longer. If you scratch the surface, zinc keeps working. Paint does not protect if it gets damaged.

- Zinc stops rust even if the coating breaks.

- Paint only covers the surface and does not protect underneath.

- Zinc works well in tough places like bridges and ships.

Tip: Choose zinc coatings if you need strong, long-lasting protection for metal.

Cost and Maintenance

You save money over time with zinc-based protection. Paint may cost less at first, but you need to repaint often. Zinc coatings last much longer, so you spend less on repairs and labor.

| Feature | Zinc Coating | Paint |

|---|---|---|

| Lasts longer | ✅ | ❌ |

| Needs repaint | Rarely | Often |

| Saves money | ✅ | ❌ |

You spend less time fixing metal when you use zinc. This means less downtime for your projects.

Environmental Considerations

You help the planet by choosing zinc-based methods. Many new zinc coatings use water instead of harsh chemicals. Paints often have more harmful fumes and waste. Zinc coatings can be recycled, so you make less trash.

Note: Zinc-based protection supports green building and cleaner air. You make a smart choice for the environment and your business.

New zinc-based technologies help metal stay safe for a long time. These solutions are better for the earth and last longer. Many businesses use them to protect their metal parts. If you want to know more, you can read new studies or ask experts.Keep learning about new ideas so your projects stay safe and work well.