You can make your plant work better with pressure-driven filtration systems. These systems help you work faster, save money, and make your plant safer. Filtration optimization is important in many industries. If you use good strategies, you help plant managers, engineers, and leaders do a better job.

Pressure-Driven Filtration Systems

Principles and Methods

Pressure-driven filtration systems help separate liquids from solids. These systems use pressure to push liquid through a filter or membrane. You can change the pressure to make the liquid move faster or slower. This helps the system work better. The method gives you cleaner liquids and keeps your process neat. Many places use this technology to take out particles or impurities from fluids.

Tip: Changing the pressure can make the system work better and cut down on waste.

Membrane Types in Industrial Applications

Industrial filtration systems use different kinds of membranes. Some membranes catch big particles. Others catch very tiny contaminants. You might pick microfiltration, ultrafiltration, or nanofiltration membranes for your job. Nanofiltration membranes remove small molecules and salts. You choose the membrane based on what you want to clean and how pure you need it. Membrane technology helps keep products clean and supports advanced filtration in factories.

Key Components

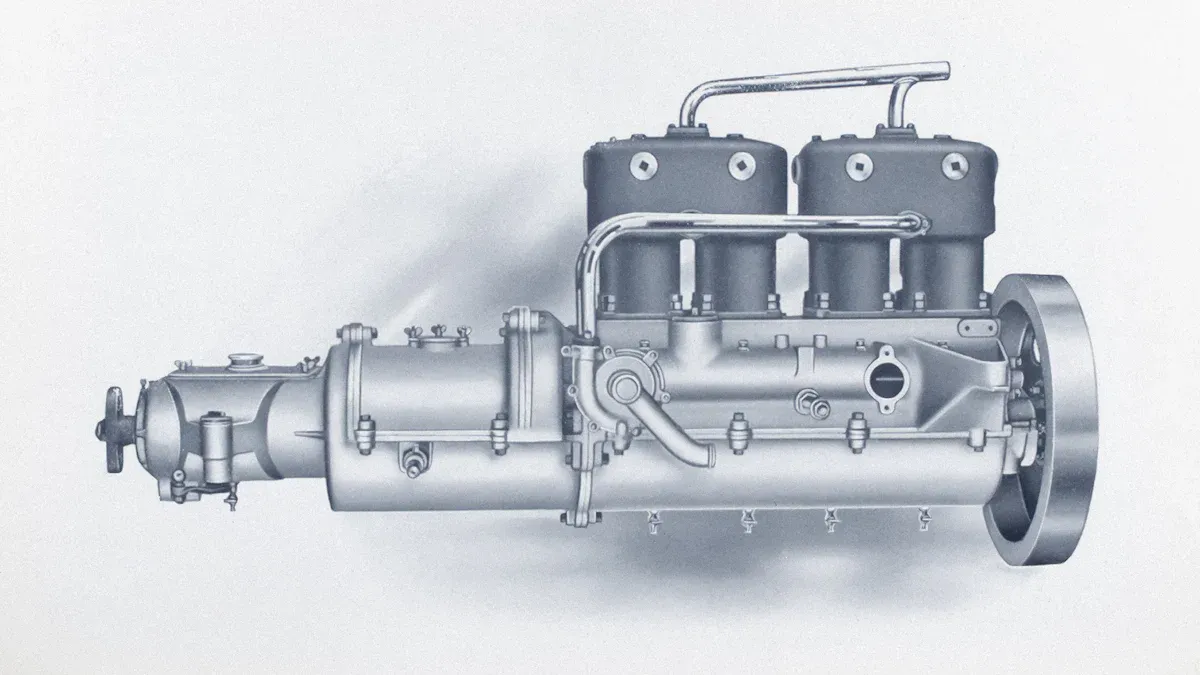

A strong pressure-driven filtration system needs several main parts. These include the filter housing, membranes, pumps, and control units. Pumps make the pressure that moves liquid through the membrane. Control units help you change settings and watch how things work. Sensors check flow rates and pressure levels.

- Filter housing keeps the membrane safe and holds everything together.

- Membranes do the filtering job.

- Pumps push the liquid.

- Sensors and controls help the system work well.

You get better results if you take care of these parts and check them often. Good care stops breakdowns and keeps your filtration system working its best.

Filtration Efficiency and Performance

Throughput and Yield

You want your plant to make more products faster. Filtration efficiency helps you get higher throughput rates. Pressure-driven filtration systems push liquids through membranes quickly. This separates solids from liquids with less work. You get more products and less waste. Adjusting the pressure helps solid-liquid separation work better. Pressure optimization lets you control how fast liquids move. You can boost yield by keeping the system clean. Checking for blockages is important.

Tip: Clean filters and regular checks help filtration work well.

Product Quality

Your customers need clean products. Filtration efficiency removes contamination from liquids. Strong membranes catch tiny particles and keep products pure. Filtration protects your plant from contamination. It helps you meet safety rules. Pressure optimization helps you pick the right settings for each batch. You can use different membranes for different jobs. Solid-liquid separation keeps unwanted stuff out of your final product.

- Good filtration gives better taste, color, and safety for food and drinks.

- Chemical plants get pure chemicals with fewer impurities.

- Water treatment gives clean water for homes and businesses.

Downtime Reduction

You want your plant to keep working without stopping. Less downtime saves money and makes your team happy. Filtration efficiency helps you avoid breakdowns and long repairs. Optimizing filtration systems helps you find problems early. You can fix them fast. Sensors and controls warn you about pressure changes or blockages.

Note: Quick action stops contamination and keeps your plant safe.

Pressure-driven filtration systems help save energy and water. Optimization helps you plan maintenance and avoid surprises. You keep your plant running and reach your production goals.

- Regular checks and smart pressure optimization keep your system strong.

- You spend less time fixing problems and more time making products.

Filtration Optimization Strategies

Optimize Filtration Processes

You can make filtration better by using two types of models. Mechanistic models explain the science behind filtration. Empirical models use real data from your plant. These models help you test different settings. You can find the best way to run your system. Pressure optimization is important. Changing pressure helps you work faster and better. Model-based frameworks predict how pressure changes affect results. This helps you avoid contamination. When you optimize filtration, you improve airflow and cut waste.

Smart filter choices are important. Nanofiltration membranes work for tough jobs. They remove tiny particles and help you meet strict rules. Pressure nutsche filters are good for batch operations. They handle solids and liquids in one step. These filters help you finish cycles faster and boost production.

Tip: Use pressure optimization to save energy and help the environment.

Maintenance Best Practices

You need to keep your filtration systems working well. Regular maintenance stops contamination and keeps your plant safe. Check membranes, pumps, and sensors often. Clean or change filters before they clog. This helps you avoid downtime and keeps things running smoothly.

Pressure nutsche filters need special care. Check seals and gaskets for leaks. Clean the filter cake area after each cycle. This stops buildup and helps your system work better. Good maintenance lowers costs and helps you make more products.

Note: Good maintenance helps you work better and supports the environment.

Monitoring and Data Analysis

Sensors and control units help you watch your filtration systems. These tools track pressure, flow rates, and filter performance. Data analysis helps you find problems early. You can use this information to change pressure settings and get better results.

Pressure optimization is very important here. You can set alerts for pressure changes. This helps you stop contamination and keep products safe. Monitoring helps you plan maintenance and avoid surprises. Using data helps you make smart choices and improve your system.

Tip: Use real-time data to make filtration better and support important strategies.

Case Studies

Many plants use pressure-driven filtration systems to work better. For example, a chemical plant switched to nanofiltration membranes and pressure nutsche filters. The plant used model-based optimization to set the best pressure for each batch. This helped the plant finish cycles faster and make more products.

Another plant made filtration better by choosing smart filters and doing regular maintenance. The team watched sensor data and changed pressure settings. This led to less downtime, lower costs, and more products.

Pressure nutsche filters helped both plants handle solids and liquids with less waste. The plants also became safer and helped the environment.

Success Story: Plants that use filtration and pressure optimization get better efficiency and product quality.

Pressure-Driven Filtration Systems can help your plant work better. You make things run smoother with good filter choices and regular care. Membrane technology helps separate liquids and keeps products clean. If you keep making your system better, it will work well for a long time. You also help the planet by making less waste and saving resources. Look at your system now and talk to experts to help your plant do its best.