Polyether Ether Ketone

High-Performance Engineering Thermoplastic

Polyether Ether Ketone

Advanced Polymer for Industrial Applications

Product Introduction

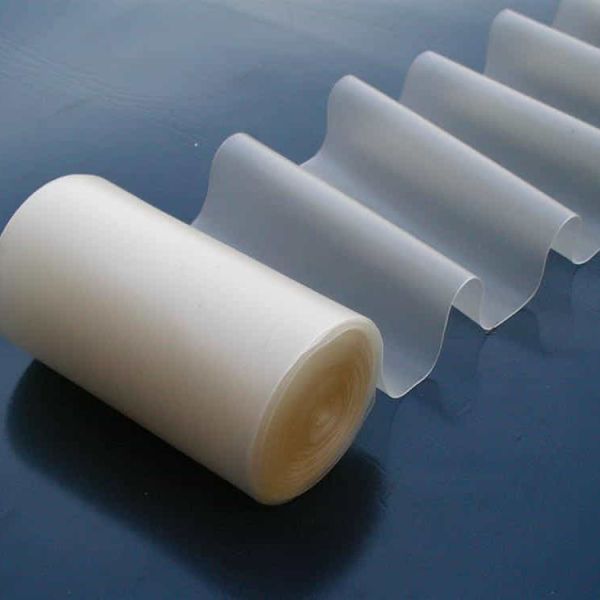

Polyether Ether Ketone (PEEK) is a premium engineering thermoplastic renowned for its exceptional mechanical properties, chemical resistance, and thermal stability. Widely utilized in various industries, including aerospace, automotive, electronics, and medical sectors, PEEK excels in applications that demand high strength, durability, and resistance to extreme conditions.

Key Features

Outstanding Mechanical Properties

- High Strength: PEEK exhibits excellent tensile and flexural strength, making it suitable for load-bearing applications.

- Durability: Provides superior wear and abrasion resistance for extended service life.

Exceptional Chemical and Thermal Resistance

- Chemical Resistance: Resistant to a wide range of chemicals, including acids, bases, and organic solvents.

- Thermal Stability: Maintains its properties at high temperatures, with a melting point around 343°C (649°F).

Electrical Insulation

- Insulating Properties: Offers excellent electrical insulation, making it ideal for electronic and electrical applications.

Biocompatibility

- Medical Applications: Biocompatible and suitable for medical implants and devices.

Specifications Table

| Property | Specification |

|---|---|

| Chemical Composition | Polyether ether ketone |

| Density | 1.30 g/cm³ |

| Melting Point | 343°C (649°F) |

| Tensile Strength | 90-100 MPa |

| Flexural Strength | 150-170 MPa |

| Elongation at Break | 20-30% |

| Glass Transition Temperature | 143°C (289°F) |

| Thermal Conductivity | 0.25 W/(m·K) |

| Electrical Resistivity | 10^16 Ω·cm |

| Water Absorption | <0.5% |

Types of PEEK

Unfilled PEEK

- Description: Standard PEEK without any fillers, offering the highest purity and mechanical properties.

- Benefits: Ideal for applications requiring maximum strength and purity.

Filled PEEK

- Description: PEEK reinforced with glass fibers, carbon fibers, or PTFE.

- Benefits: Enhanced mechanical and thermal properties for specialized applications.

Medical Grade PEEK

- Description: Biocompatible PEEK suitable for medical implants and devices.

- Benefits: Meets stringent medical standards for safety and performance.

Applications

Aerospace Industry

- Usage: Used in aircraft components and structural parts.

- Benefits: Provides high strength-to-weight ratio and excellent thermal stability.

Automotive Industry

- Usage: Ideal for manufacturing engine components, bearings, and seals.

- Benefits: Offers durability and resistance to high temperatures and chemicals.

Electronics

- Usage: Suitable for electronic connectors, insulators, and semiconductor equipment.

- Benefits: Provides good electrical insulation and thermal stability.

Medical Devices

- Usage: Used in spinal implants, dental implants, and surgical instruments.

- Benefits: Biocompatible and suitable for long-term implantation.

Industrial Applications

- Usage: Ideal for pump components, valve seats, and compressor parts.

- Benefits: Provides excellent wear resistance and mechanical strength.