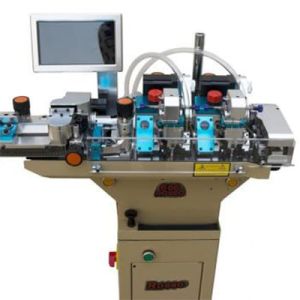

Automatic Film Applicator

Precise and Reproducible Coating automatic film applicator

manufacturer: Marjan Polymer Industries pakistan

Model # MAF-400

Product Introduction

Unlock precision and consistency with the Automatic Film Applicator, engineered for uniform film application and reliable performance in laboratory and industrial settings. This high-performance film applicator machine ensures even coating thickness and repeatable results, making it an essential tool for quality control, research, and development.

Perfectly designed for professionals, the automatic film coater combines advanced automation with accuracy — eliminating human error and ensuring flawless coating application across various substrates.

Key Features

- Uniform Coating Precision — It ensures controlled film thickness for consistent, repeatable, and high-quality surface coatings.

- Versatile Application — Compatible with multiple film applicator tools and substrates, making it ideal for paint, varnish, adhesive, and resin testing.

- Adjustable Speed & Pressure — Fully customizable settings provide precise control, whether you’re using an automatic film coating machine or a manual film applicator setup.

- Durable & Reliable Design — Built for long-term performance with robust components and stable operation, ensuring accurate film application every time.

- Ease of Use — Simple controls and efficient setup make this adjustable film applicator user-friendly for both experts and technicians.

Specifications Table

| Feature | Specification |

|---|---|

| Configuration | Automatic Film Applicator |

| Traversing Speed | ~ 1 ~ 160mm/sec |

| Stroke Length | 400 mm |

| Overall Speed & Distance | Adjustable, variable |

| Controllable Distance | ~ 400mm |

| Draw Down Bed Size | 400 ~ 450 x 300mm (L x W) |

| Coating Plate | Flat Aluminum Vacuum plate with 1mm holes |

| Additional Accessory | External glass plate for easy attachment/detachment |

| Vacuum Bed | High precision vacuum suction-gas bed plate |

| Temperature Range | Room temperature ~ 150°C |

| Heating Power | ~ 2000W |

| Electric Power | 220-230V, 50/60 Hz |

| Display | Digital display of settings, temperature, & coating speed |

| Vacuum Pump | Included |

| Doctor Blade Film Coater | Width 300mm, thickness up to 5mm with precision approx. 10um |

How to use?

Place your substrate on the platform, set the desired coating parameters, and let the Automatic Film Applicator glide the film applicator tool smoothly across the surface. Adjust speed and pressure as needed to achieve uniform coating. Clean the equipment after each use for best results and long-term reliability.

Essential Accessories

- Vacuum Pump: Supports materials for precise application.

- Doctor Blade Film Coater: Width 300mm, thickness up to 5mm with precision approx. 10um.

- External Glass Plate: Additional accessory for easy attachment/detachment on the aluminum plate.

Warranty

Limited Warranty

- Duration: 12 months limited warranty on parts and after-sales services.

- Exclusions: Excludes consumables, user-damaged parts, and damages caused by electrical failures, fire, or natural disasters.

Why Buy from Marjan Polymer?

-

Authentic, industry-grade products trusted by laboratories and research professionals.

-

Competitive pricing and availability of the Automatic Film Applicator across Pakistan.

-

Expert technical guidance and fast, reliable delivery for your convenience.

Price

Automatic Film Applicator price in Pakistan is highly competitive. Order yours today from Marjan Polymer Pakistan – your reliable partner for advanced industrial and laboratory solutions.