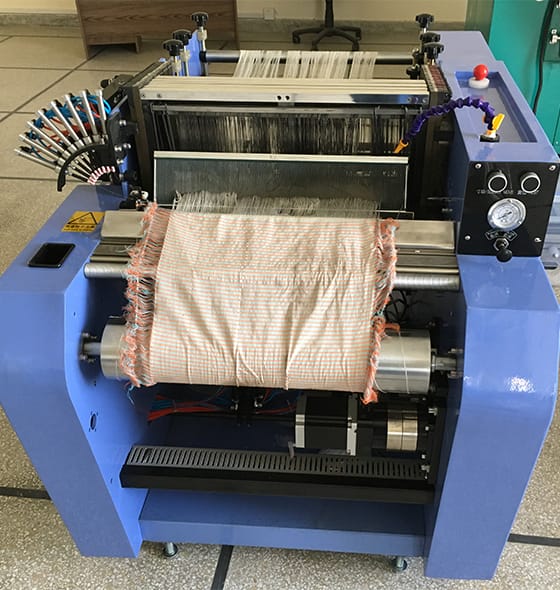

Braiding Machine

High-Performance Braiding Machine for Carbon Fiber and Glass Fiber

Advanced Braiding Technology for Composite Materials

Introduction

The Braiding Machine is a state-of-the-art equipment designed for the efficient and precise braiding of carbon fiber and glass fiber materials. This high-performance machine is ideal for producing braided composites used in aerospace, automotive, marine, and industrial applications. With its advanced features and robust construction, the Braiding Machine ensures superior quality and consistency in every braid.

Why Choose Our Braiding Machine?

Our Braiding Machine stands out due to its exceptional precision, reliability, and versatility. It is engineered to handle a wide range of materials, making it an indispensable tool for any industry requiring high-quality braided composites. Whether you are in aerospace manufacturing or producing high-strength marine ropes, this machine delivers unmatched performance.

Technical Overview

Robust Construction

- High-Quality Materials: The machine is constructed from high-grade stainless steel and aluminum, ensuring durability and resistance to corrosion.

- Sturdy Frame: Designed to withstand the rigors of continuous industrial use, providing long-lasting performance.

Precision Braiding

- High-Precision Mechanisms: The machine uses advanced gearing and spindle mechanisms to achieve precise braiding patterns, essential for uniformity and strength in the final product.

- Adjustable Braiding Pitch: Allows for customization of the braid tightness, accommodating various application requirements.

Advanced Control Systems

- Digital Control Panel: The user-friendly interface allows operators to easily set and monitor parameters such as speed, tension, and braiding pattern.

- Inverter Controlled Speed Adjuster: Ensures smooth and accurate control over the braiding and drag speeds, enhancing operational flexibility.

Key Features

- Multiple Spindles and Bobbins: Equipped with 56 spindles and 112 bobbins, enabling complex braiding patterns and high productivity.

- Yarn Breaking Auto-Stop Sensor: Automatically stops the machine if a yarn breaks, preventing defects and ensuring product quality.

- Energy Efficient: Designed to optimize power consumption without compromising on performance.

- Compact and Space-Efficient: Despite its robust capabilities, the machine has a compact footprint, making it suitable for facilities with limited space.

Specifications

| Specification | Details |

|---|---|

| Model | 56 Spindles Braiding Machine |

| Materials | Carbon, Jute, Glass, etc. |

| Type | Horizontal Type Braiding Machine |

| No. of Spindles | 56 (customizable 72, 96 etc.) |

| No. of Bobbins | 112 (customizable) |

| No. of Heads | Single Head |

| Bobbin Size | Φ 48 x 140 mm |

| Rope Diameter | ~ 3 – 20 mm |

| Gear Size | 90 mm (customizable) |

| Yarn Breaking Auto-Stop | Equipped |

| Braiding Pitch | Adjustable |

| Motor Power | 380 V, 0.75 Kw |

| Speed | 150 – 250 RPM (customizable) |

| Speed Adjuster | Inverter Controlled |

| Dimensions | 1.3 x 2 x 1.7 meters |

| Weight | ~ 700 Kg |

| Accessories | All standard accessories included |

Applications

The Braiding Machine is suitable for a variety of applications:

- Aerospace Components: Ideal for creating lightweight and strong braided composites used in aircraft structures.

- Automotive Parts: Produces high-strength components for vehicles, enhancing durability and performance.

- Marine Structures: Creates corrosion-resistant braided materials for ropes and cables used in marine environments.

- High-Pressure Hoses: Perfect for manufacturing hoses that require high durability and flexibility.

- Electrical Cables and Wires: Ensures precise braiding for shielding and insulation purposes.

Installation and Training

Professional installation and training services ensure seamless integration into your manufacturing process. Our factory-trained engineers and technicians provide comprehensive training to your staff, ensuring maximum productivity and efficiency from day one.

Warranty Information

This machine comes with a 12-month limited warranty for parts and after-sales services, excluding consumable parts and damages caused by misuse or natural disasters. This warranty provides peace of mind and ensures long-term reliability.