Flexible Epoxy Resin

High-Performance Flexible Epoxy Resin

Advanced Flexible Epoxy Resin by Resoltech Spain

Product Introduction

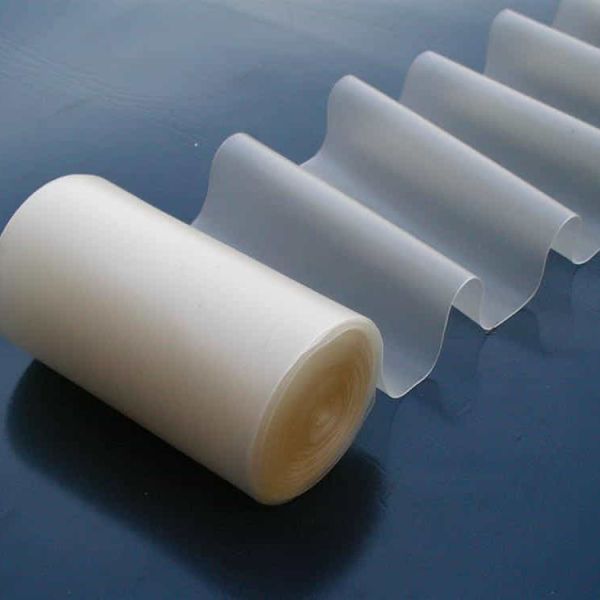

The Flexible Epoxy Resin by Resoltech Spain, specifically the Resoltech 1600 / 1606 system, is designed to provide high flexibility and impact resistance while retaining the core benefits of epoxy resins such as high adhesion and toughness. This advanced formulation addresses aging issues found in older flexible epoxy systems, making it ideal for a variety of industrial and specialized applications.

Key Features

High Flexibility and Impact Resistance

- Flexible Laminating System: Suitable for applications requiring high flexibility and improved impact resistance.

- Room Temperature Curing: Allows for easy and efficient processing without the need for elevated temperatures.

Robust Construction

- Advanced Insulation: Built with high-temperature resistant materials and advanced insulating fibers.

- High Adhesion: Excellent adhesion on all substrates, ensuring durability and reliability.

User-Friendly Design

- Comfortable Working Time: Provides ample working time for application and adjustments.

- Easy Application: Designed for straightforward use in various industrial settings.

Versatile Applications

- Wide Range of Uses: Suitable for applications such as flexible carbon rods, light RTM counter moulds, decoration items, rally car parts, sensors encapsulation, and fibre reinforced membranes.

Specifications Table

| Feature | Specification |

|---|---|

| Mix Density | 1.06 |

| Mix Viscosity (mPa.s) | 500 |

| Gel Time on 70 mL, 4cm at 23°C | 3h40m |

| Glass Transition Temperature (TG) | -44°C |

| Thermocouple Type | S – Type thermocouple |

| Heating Elements Type | Molybdenum Disilicide (MoSi2) Super Kanthal |

| Stability | ± 5°C |

| Homogeneity | ± 5% |

| Inner Dimensions | 150 x 150 x 150 mm (height x width x depth) |

| Workable Capacity | 3.4 Liters |

| Outer Dimensions | 750 x 450 x 600 mm (height x width x depth) |

| Electric Specifications | Control system, Ramp programmer with 4 programs, 15 segments |

| Power Adjustment | Tyristor equipment |

| Power | 4Kw, 50-60 Hertz |

| Voltage | 220V |

| Weight | ~ 100 Kg |

Types of Epoxy Systems

Standard Flexible Epoxy Resin

- Description: Ideal for general-purpose flexible applications.

- Benefits: Provides reliable and consistent performance across various uses.

High-Performance Flexible Epoxy Resin

- Description: Designed for applications requiring enhanced flexibility and impact resistance.

- Benefits: Ensures durability and reliability in demanding environments.

Customizable Flexible Epoxy Resin

- Description: Tailored to meet specific application requirements.

- Benefits: Offers flexibility and precision for specialized processes.

Applications

Industrial Adhesives

- Usage: Used in bonding fibers and other materials requiring flexibility.

- Benefits: Provides strong adhesion while maintaining flexibility.

Automotive Components

- Usage: Ideal for manufacturing flexible and impact-resistant parts for vehicles.

- Benefits: Ensures durability and reliability in automotive applications.

Decorative and Upholstery Items

- Usage: Suitable for creating flexible decorative pieces and upholstery items.

- Benefits: Delivers high-quality finishes and durability.

Sensors Encapsulation

- Usage: Used for encapsulating sensors to protect them while maintaining flexibility.

- Benefits: Ensures the longevity and reliability of encapsulated sensors.

Accessories and Tools Included

Essential Accessories

- Mixing Tools: Various tools for accurate mixing of the epoxy resin and hardener.

- Application Tools: Spatulas, brushes, and rollers for easy application.

Additional Tools

- Cleaning Kit: Ensures easy maintenance and cleaning of application tools.

- User Manual: Provides detailed instructions for mixing, application, and maintenance.