Optically Brightened Laminating Epoxy

High-Performance Enhanced Clarity Resin

Resoltech Spain Grade: Optically Brightened Laminating Epoxy

Product Introduction

Optically Brightened Laminating Epoxy by Resoltech Spain is an advanced, high-performance resin designed to provide enhanced clarity and brightness for laminating applications. This epoxy resin is formulated with optical brighteners to deliver a brilliant, crystal-clear finish, making it ideal for high-visibility and aesthetic applications. Perfect for use in marine, automotive, aerospace, and artistic projects, this resin ensures a smooth, bubble-free finish with exceptional mechanical properties and UV resistance.

Key Features

Enhanced Clarity and Brightness

- Optical Brighteners: Formulated with optical brighteners to deliver a brilliant, crystal-clear finish.

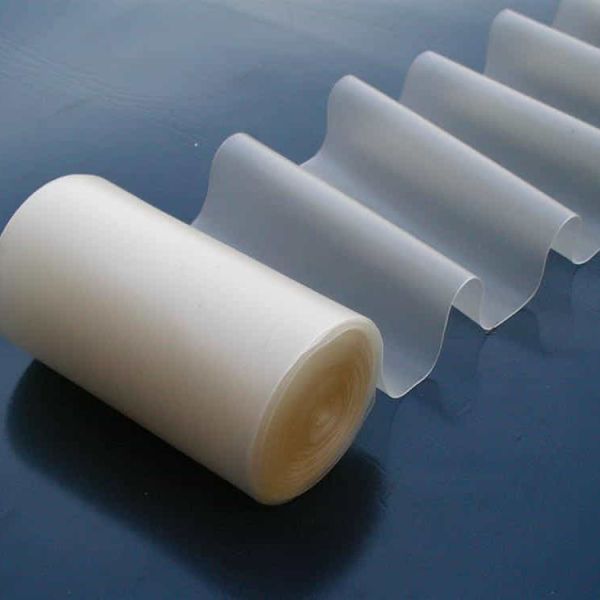

- Transparency: Provides unparalleled clarity, perfect for high-visibility laminates.

Superior Mechanical Properties

- High Adhesion: Bonds well to various reinforcement fibers, including carbon, glass, and natural fibers.

- Durability: Ensures long-lasting performance with excellent resistance to impacts and abrasion.

UV and Weather Resistance

- UV Resistance: Resists yellowing and degradation from UV exposure, maintaining clarity over time.

- Weather Resistance: Provides excellent durability in outdoor and harsh environmental conditions.

Easy Application

- Two-Part System: Easy-to-mix 2:1 ratio for straightforward application.

- Low Viscosity: Allows for easy mixing and application, ensuring a smooth finish.

- Curing Options: Can be cured at room temperature or accelerated with heat for faster processing times.

Specifications Table

| Feature | Specification |

|---|---|

| Manufacturer | Resoltech Spain |

| Grade | Optically Brightened Laminating Epoxy |

| Composition | Two-part epoxy |

| Mix Ratio | 2:1 (resin) |

| Working Time | 60 minutes |

| Cure Time | 24 hours at room temperature, 2 hours at 60°C |

| Hardness | Shore D 85 |

| UV Resistance | High |

| Clarity | Enhanced optical brightness |

| Viscosity | Low |

| Packaging | Available in various sizes |

Types of Epoxy Resins

Standard Epoxy Resin

- Description: Provides reliable bonding for general-purpose applications.

- Benefits: Offers a balance of strength, durability, and versatility.

High-Temperature Epoxy Resin

- Description: Specifically formulated for high-temperature environments.

- Benefits: Maintains bond strength and integrity under extreme heat.

Chemical-Resistant Epoxy Resin

- Description: Provides enhanced resistance to chemicals and solvents.

- Benefits: Ensures long-lasting performance in chemically aggressive environments.

Applications

Marine and Automotive

- Usage: Ideal for creating clear, durable laminates for marine and automotive applications.

- Benefits: Provides excellent resistance to water and UV exposure, ensuring longevity and durability.

Aerospace and Defense

- Usage: Suitable for producing high-performance, visually appealing aerospace components.

- Benefits: Ensures lightweight, durable, and high-strength composite laminates.

Artistic and Decorative

- Usage: Perfect for laminating artwork, sculptures, and decorative pieces.

- Benefits: Provides a clear, protective finish that enhances the visual appeal of artistic creations.

Furniture and Woodworking

- Usage: Used for laminating and coating in furniture and woodworking projects.

- Benefits: Offers a clear, durable layer that highlights the natural beauty of wood and other materials.