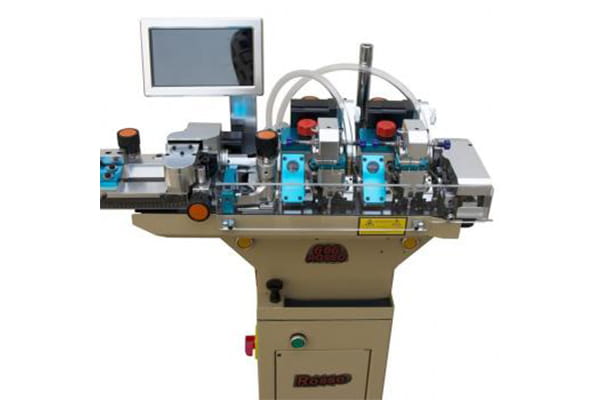

Three Roll Mill

High-Efficiency Mixing and Dispersion Solution

Three Roll Mill for Mixing Nanoparticles in Polymers & Paints

Product Introduction

The Three Roll Mill is a unique roll mixer widely used for mixing and dispersion of paste materials, including inks, paints, coatings, pigments, soap, artificial leather, plastics, lubricants, greases, polymers, resins, and chocolates. This advanced mill is particularly effective for high-viscosity and fine materials. Manufactured with high-hardness alloy rolls and equipped with a cooling device, it ensures efficient and continuous operations. Ideal for research, quality control, and industrial applications, this mill enhances material consistency and performance.

Key Features

Superior Mixing and Dispersion

- High Efficiency: Ensures thorough mixing and dispersion of high-viscosity and fine materials.

- Uniform Consistency: Provides consistent and high-quality mixtures for various applications.

Robust Construction

- High-Hardness Alloy Rolls: Made of high-hardness alloy, the rolls are designed to withstand heavy use and resist abrasion.

- Cooling Device: Equipped with a cooling device for continuous operation without overheating.

Versatile Applications

- Wide Range of Materials: Suitable for inks, paints, coatings, pigments, soap, artificial leather, plastics, lubricants, greases, polymers, resins, and chocolates.

- High Viscosity Materials: Particularly effective for processing high-viscosity materials.

User-Friendly Design

- Adjustable Roll Speed: Roll speed ranges from 28 to 152 rpm, allowing for precise control.

- Compact and Efficient: Designed for ease of use and efficient operation in various settings.

Specifications Table

| Properties | Technical Parameters |

|---|---|

| Roller Diameter | 100 mm |

| Working Length | 250 mm |

| Roll Speed | 28 – 152 rpm |

| Motor Power | 1.5 KW |

| Capacity | 30 Liters |

| Overall Size | 680 x 600 x 700 mm |

| Weight | 300 Kg |

Types of Three Roll Mills

Laboratory Three Roll Mill

- Description: Ideal for small-scale research and development.

- Benefits: Provides precise control for developing new formulations and materials.

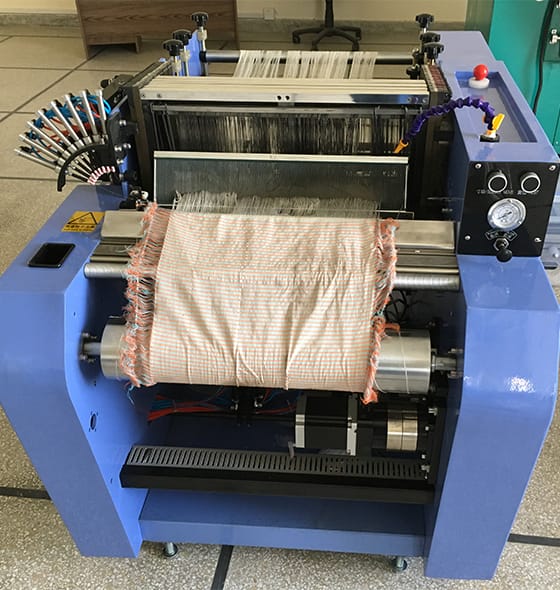

Industrial Three Roll Mill

- Description: Designed for large-scale production and continuous operations.

- Benefits: Ensures consistent and efficient processing of high-viscosity materials.

High-Viscosity Three Roll Mill

- Description: Specifically engineered for mixing and dispersing high-viscosity materials.

- Benefits: Delivers uniform consistency and high-quality mixtures.

Applications

Paints and Coatings

- Usage: Used in the production of high-quality paints and coatings.

- Benefits: Ensures uniform dispersion of pigments and additives for superior performance.

Polymers and Resins

- Usage: Ideal for mixing and dispersing polymers and resins.

- Benefits: Enhances the consistency and quality of polymer and resin-based products.

Inks and Pigments

- Usage: Used in the formulation of inks and pigments.

- Benefits: Provides uniform dispersion and high-quality finished products.

Lubricants and Greases

- Usage: Suitable for mixing high-viscosity lubricants and greases.

- Benefits: Ensures consistent performance and stability in lubricants and greases.

Accessories and Tools Included

Essential Accessories

- Cooling Device: Included to prevent overheating during continuous operation.

- Adjustable Speed Control: Allows for precise adjustment of roll speed.

Additional Tools

- Cleaning Kit: Ensures easy maintenance and cleaning of the mill.

- User Manual: Provides detailed instructions for operation and maintenance.

Installation and Training

Comprehensive Installation Services

- Process: Complete installation and setup by factory-trained engineers and technicians.

- Seamless Integration: Ensures smooth integration into your laboratory or production facility, minimizing downtime and maximizing efficiency.

Thorough Training Programs

- Training: Extensive training for your staff, covering operational and maintenance aspects.

- Benefits: Maximizes productivity and efficiency by ensuring your team is well-versed in using the mill.

Warranty

Limited Warranty

- Duration: 12 months limited warranty on parts and after-sales services.

- Exclusions: Excludes consumables, user-damaged parts, and damages caused by electrical failures, fire, or natural disasters.