Complete Non-woven Fabric Line

Needle Loom

(For processing sheep wool fibers)

Cleaning unit, Opening units, Cross Lapping, Needle Punching, Winder

Product Introduction

The Needle Loom by Marjan Polymer Industries is designed for high-efficiency needle punching processes. This advanced machinery is ideal for producing non-woven, asphalt felt substrates, and geotextiles. It features pre-needling, upstroke, and down-stroke structural styles, making it versatile for various applications in the textile industry.

Key Features and Specifications of Neelde Loom

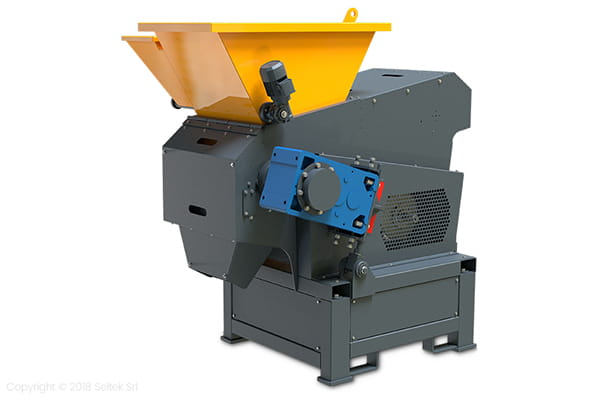

1. Pre-Fiber Opener

Use and Characteristics:

- Loosens fiber bundles and transfers them to the next stage via a blower fan.

- Reduces fiber damage with a notch-style roller.

- Equipped with a strong magnet to remove metal impurities.

Specifications:

- Machine Width: ~400mm

- Production Capacities: 20-50kg/h

- Power: ~5kw

2. Feeding Machine

Use and Characteristics:

- Mixes opened fibers and transfers an even cotton layer to the next stage.

- Utilizes photoelectric constant-weight control and a vibrating plate for accurate feeding.

Specifications:

- Machine Width: ~500mm

- Production Capacities: 20-50kg/h

- Power: 2.25kw

3. Carding Machine

Use and Characteristics:

- Suitable for combing artificial fibers (1.5-20D × 38-65mm).

- Ensures fully combed fibers and an even mesh.

- Equipped with a frequency conversion-driven feeding roller and anti-metal protection.

Specifications:

- Working Width: 500mm

- Cylinder Diameter: ~500mm

- Output Capacity: ~3 Kg/h

- Speed: ~20-50m/min

- Power: ~5kw

4. Cross Lapper

Use and Characteristics:

- Folds and paves the mesh after carding into a specified width and thickness.

- Transfers mesh to the next stage after pressurization.

- Features separate drive for paving aprons and frequency conversion-controlled reciprocal commutation.

Specifications:

- Input Apron Width: 500mm

- Output Apron Width: 1000mm

- Belts: PVC

- Lapping Speed: 0-45m/min (variable)

- Power: ~5kw

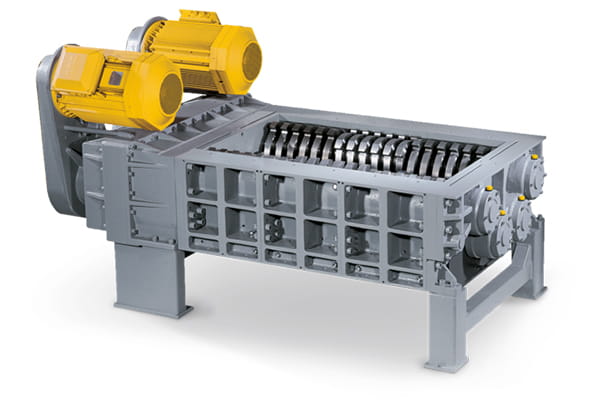

5. Needle Punching Machine

Use and Characteristics:

- Suitable for producing common non-woven, asphalt felt substrates, and geotextiles.

- Features pre-needling, upstroke, and down-stroke structural styles.

Specifications:

- Working Width: 1000mm

- Needle Stroke: 55-60mm

- Needle Density: 4000-5000s/m

- Punching Frequency: 100-600m/min (variable)

- Power: ~5kw

6. Winding & Cutting Machine

Use and Characteristics:

- Cuts the required width length for packing at the rear procedure of the nonwoven production line.

Specifications:

- Machine Width: 1000mm

- Liner Speed: 1-15m/min

- Power: 1.5kw

Installation and Training

Installation:

Complete installation and commissioning (needle loom) by factory-trained engineers/technicians. End-user to arrange any required civil work.

Training:

Comprehensive training (needle loom) provided to operators by factory-trained personnel at the customer’s location.

Warranty and Support

12-month limited warranty covering parts and after-sales services, excluding consumable parts and damages caused by user mishandling, electrical failures, fire, or natural disasters.

Contact Information

For more information or to place an order, please contact:

Marjan Polymer Industries

Email: info@marjanpolymer.com

Phone: +92-321-9993-919