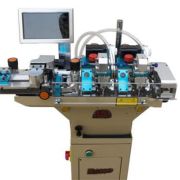

Toe Closing Machine

Advanced Sock Toe Closing Solution

Product Introduction

The Toe Closing Machine is a high-performance equipment designed for efficiently closing the toes of socks, ensuring a seamless and comfortable finish. This machine is ideal for use in textile manufacturing, particularly in the production of socks for various applications. Engineered with advanced technology, the Toe Closing Machine provides precise and reliable performance, making it indispensable for sock manufacturers aiming to enhance product quality and production efficiency.

Key Features

Superior Closing Precision

- High Accuracy: Ensures precise toe closing for a seamless finish.

- Consistent Performance: Provides consistent and reliable results, enhancing the quality of socks.

Robust Construction

- Durable Materials: Constructed from high-quality materials to withstand rigorous use and ensure long-lasting performance.

- Adjustable Settings: Features adjustable parameters for precise control over the closing process.

User-Friendly Design

- Easy Operation: Intuitive controls and interface for easy setup and operation.

- Automatic Functions: Includes automatic functions for enhanced efficiency and productivity.

Versatile Applications

- Wide Range of Socks: Suitable for closing toes on various types of socks, including sports, fashion, and medical socks.

Specifications Table

| Feature | Specification |

|---|---|

| Machine Type | Automatic Toe Closing Machine |

| Speed | Adjustable |

| Power | Variable (customizable based on requirements) |

| Voltage | 220-240V, 50/60 Hz |

| Dimensions | Varies by model |

| Weight | Varies by model |

| Control System | PLC-based automated control |

| Data Output | USB, Ethernet |

| Air Consumption | 0.45 – 0.75 MPA, MAX 350/min |

| Electric Specifications | Control system, Programmable functions |

Types of Toe Closing Machines

Standard Toe Closing Machine

- Description: Ideal for general-purpose sock manufacturing.

- Benefits: Provides reliable and consistent toe closing for various sock designs.

High-Speed Toe Closing Machine

- Description: Designed for high-speed and high-volume production.

- Benefits: Ensures efficient and large-scale manufacturing of socks.

Customizable Toe Closing Machine

- Description: Tailored to meet specific application requirements.

- Benefits: Offers flexibility and precision for specialized processes.

Applications

Sports Socks

- Usage: Used in the production of high-quality sports socks.

- Benefits: Ensures a comfortable and seamless finish for athletic use.

Fashion Socks

- Usage: Ideal for manufacturing fashionable and high-quality socks.

- Benefits: Provides consistent quality and design accuracy for fashion brands.

Medical Socks

- Usage: Suitable for producing medical and therapeutic socks.

- Benefits: Ensures precise construction for specialized medical applications.

Accessories and Tools Included

Essential Accessories

- Needle Sets: Various needle sets for different sock types and sizes.

- Thread Cutters: High-quality thread cutters for a clean finish.

Additional Tools

- Cleaning Kit: Ensures easy maintenance and cleaning of the machine.

- User Manual: Provides detailed instructions for operation and maintenance.

Installation and Training

Comprehensive Installation Services

- Process: Complete installation and setup by factory-trained engineers and technicians.

- Seamless Integration: Ensures smooth integration into your production facility, minimizing downtime and maximizing efficiency.

Thorough Training Programs

- Training: Extensive training for your staff, covering operational and maintenance aspects.

- Benefits: Maximizes productivity and efficiency by ensuring your team is well-versed in using the machine.

Warranty

Limited Warranty

- Duration: 12 months limited warranty on parts and after-sales services.

- Exclusions: Excludes consumables, user-damaged parts, and damages caused by electrical failures, fire, or natural disasters.