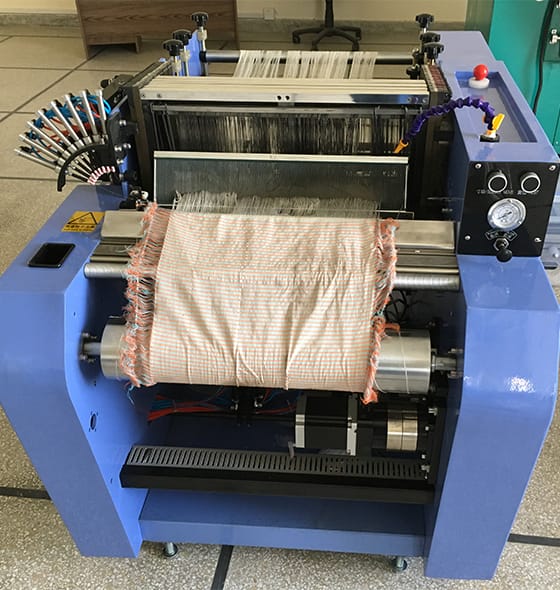

Waterjet Loom

Advanced Waterjet loom Weaving Machine

High-Efficiency Weaving for Textile Applications

Introduction

The Waterjet Loom is a high-performance weaving machine designed for efficient and precise textile production. Utilizing advanced waterjet technology, this loom ensures high-speed weaving with exceptional fabric quality. It is ideal for textile manufacturers aiming to enhance their production capabilities and achieve superior fabric quality. The machine’s robust design and innovative features make it an indispensable tool for modern textile production.

Key Features

- High-Speed Weaving: Operates at speeds up to 650 rpm, enabling rapid production without compromising quality.

- Waterjet Weft Insertion: Ensures precise and efficient weft insertion, improving fabric integrity and consistency.

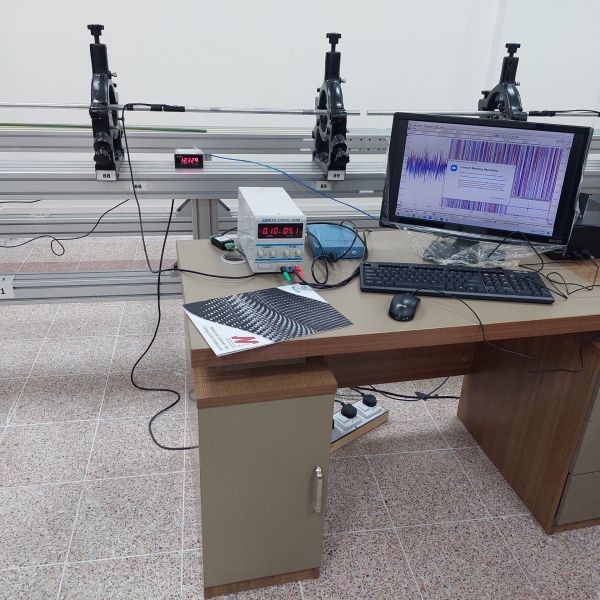

- Positive Cam/Dobby Shedding: Equipped with CAD designing software for advanced shedding control and design capabilities.

- Electronic Let-Off and Take-Up: Provides accurate tension control and consistent fabric density.

- Advanced Control System: Includes a user-friendly interface with Scotweave Dobby & Jacquard software for enhanced design and operation.

- Robust Construction: Built with a durable frame and high-quality components to withstand rigorous industrial use.

Types

- Standard Model YC822: Ideal for general textile weaving applications, offering reliable and efficient performance.

- High-Capacity Model: Designed for large-scale textile production, providing enhanced capacity and speed.

- Specialized Model: Tailored for specific fabric types and weaving requirements, ensuring optimal performance and efficiency.

Applications

- Textile Manufacturing: Essential for producing high-quality woven fabrics for various applications.

- Fashion and Apparel: Suitable for creating intricate and high-quality fabrics for clothing and fashion accessories.

- Home Textiles: Used in the production of durable and aesthetically pleasing home textile products.

- Industrial Textiles: Ideal for manufacturing technical textiles and fabrics for industrial applications.

- Educational Institutions: Provides practical training and research opportunities for textile engineering students and researchers.

Specifications

| Specification | Details |

|---|---|

| Working Width | 1000 mm |

| Frame Numbers | 4 pcs |

| Shedding Type | Positive Cam / Dobby with CAD Designing Software |

| Speed | 650 rpm |

| Weft Insertion | Waterjet |

| Number of Weft Selectors | 2 |

| Number of Heald Frames | 4 |

| Let-Off and Take-Up | Electronic |

| CAM | Positive CAM 10 shafts |

| Beam | 1 PC 100 cm |

| Roller | 1 PC roller |

| Motor | ~ 1.5 kW |

| Nozzle | MDH4520 |

| Single Valve | Titanium |

| Crankshaft Motion | Degrees |

| Single Nozzle | Adopted |

| Heald Length | 4 pcs 100 cm |

| Cross Beam | Thick triangle-shaped tube |

| Painting Processing | Acid wash phosphate spray |

| Panel | Thick aluminum alloy |

| Crossbeam Trestle | Central vertical trestle according to the width |

| CAD Designing Software | Scotweave Dobby & Jacquard combined designer software |

| PC for Operation | 4 PCs, Intel Core i7, 1TB HDD, 18-inch LCD, keyboard, mouse, data cables, CD ROM, RAM, 4GB USB drive |

Accessories

- Replacement Nozzles: Available in various sizes to accommodate different weaving needs.

- Tension Control Devices: Ensure precise tension management for consistent fabric quality.

- Maintenance Kits: Includes essential tools and components for routine maintenance.

- Cleaning Equipment: Tools and materials for easy cleaning of the waterjet components and other parts.

Installation and Training

Comprehensive installation guidelines are provided to ensure proper setup and operation. Training sessions can be arranged upon request to educate users on the correct usage, maintenance, and troubleshooting of the Waterjet Loom. This ensures maximum efficiency and longevity of the equipment.

Warranty Information

- Standard Warranty: 12 months limited warranty covering parts and after-sales services, except for consumable parts and damages caused by user errors, electrical failures, fires, or natural disasters.