Cross Flow Membrane Filtration System

Advanced Filtration Technology

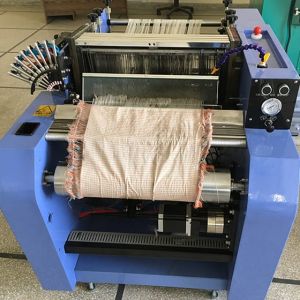

High-Performance Cross Flow Membrane Filtration

Product Introduction

Experience superior separation and purification with the Cross Flow Membrane Filtration System—engineered to deliver unmatched efficiency for industrial and commercial processes. This cutting-edge technology uses membrane filtration to ensure consistent results, reduce waste, and optimize production performance.

Key Features

High-Efficiency Separation — Utilizes advanced membrane filtration to achieve precise liquid-solid separation.

Extended Membrane Life — Innovative design reduces fouling and prolongs membrane filtration lifespan.

Energy-Efficient Operation — Minimizes energy consumption while maintaining maximum throughput.

Versatile Applications — Ideal for food, beverage, pharmaceutical, and water treatment industries.

Specifications Table

| Feature | Specification |

|---|---|

| Model Number | MF 25 |

| Filtration Assembly | Polymer membrane filters (90mm diameter) |

| Pressure Range | 1-40 bar |

| Temperature Range | Room Temp – 80°C |

| Pump Type | High-pressure pump |

| Control | On/off control, backpressure valve for pressure adjustment |

| Sensors | Electronic pressure sensor, electronic temperature sensor (thermocouple) |

| Data Logging | Yes |

| Diafiltration Capability | Yes, with peristaltic pump and high-level sensor |

| Software Features | Specifies mass of permeate collected before water/buffer addition, plots permeate flow rate over time |

Applications

Connect the Membrane Filtration System to your process line.

Ensure proper flow and pressure settings for the desired separation level.

Monitor performance through the integrated control system for consistent, high-quality output.

Why Buy From Marjan Polymer?

Official supplier of high-performance industrial solutions in Pakistan

Competitive pricing and guaranteed product authenticity

Expert guidance and reliable after-sales support

Limited Warranty

- Duration: 12-month limited warranty on parts and after-sales services.

- Exclusions: Excludes consumables, user-damaged parts, and damages caused by electrical failures, fire, or natural disasters.

Order today from Marjan Polymer—offering the best price of Cross Flow Membrane Filtration System in Pakistan.