Twin Screw Extruder

Advanced Extrusion Technology

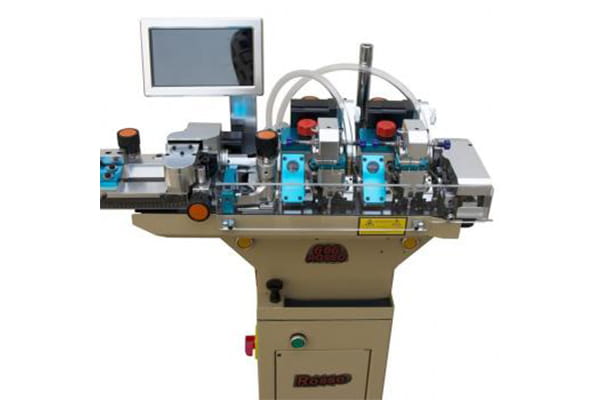

High-Performance Twin Screw Extruder

Product Introduction

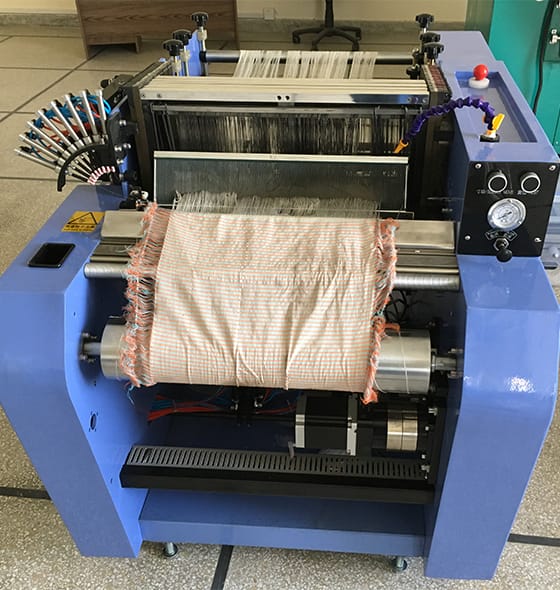

The Twin Screw Extruder by Marjan Polymer Industries is a cutting-edge extrusion machine designed for efficient mixing and processing of various materials. Ideal for applications in polymers, rubber, and food industries, this high-performance extruder ensures precise control over the extrusion process. With robust construction and advanced features, it delivers reliable operation and superior quality output.

Key Features

Superior Mixing and Extrusion

- High Efficiency: Delivers uniform mixing and consistent extrusion of materials.

- Versatile Applications: Suitable for processing plastics, rubber, and food products.

Robust Construction

- Durable Materials: Fabricated with high-quality stainless steel for longevity and corrosion resistance.

- Advanced Insulation: Features advanced insulating materials to minimize heat loss and enhance energy efficiency.

User-Friendly Design

- Easy Operation: Intuitive controls and interface for easy setup and operation.

- Automated Functions: Includes automated functions to boost efficiency and productivity.

Precise Control

- Temperature Control: Offers precise temperature control for accurate and consistent results.

- Pressure Control: Equipped with a pressure relief valve and vacuum gauge for monitoring and control.

Specifications Table

| Feature | Specification |

|---|---|

| Material of Construction | Stainless steel |

| Mixing Augers | Dual-sided mixing screws/augers |

| Nozzle Diameter | 3” – 4” |

| Max. Batch Capacity | 20-25 Kg |

| Hopper Size | 9” to 12” |

| Clay Cut-off | Wired cutting system |

| Conveyor | Receiving conveyor table for extruded material |

| Collection Chamber | Coated with “Cold Galvanizing Compound” |

| Vacuum Mixing | Integrated vacuum mixing system |

| Pressure Valve | Vacuum pressure relief valve |

| Vacuum Gauge | Continuous vacuum monitoring |

| Vacuum Pump | Oil-free vacuum pump included |

| Motor | Min. 1 HP Gear Driven Motor |

| Power | 220V, 50/60 Hz |

| Dual Safety System | Limit switch and overload protection |

| Extruding Die | Stainless steel dies, multi-dimensional |

| Roller Shelf | Stainless steel roller shelf |

Types of Twin Screw Extruders

Standard Twin Screw Extruder

- Description: Ideal for general-purpose mixing and extrusion applications.

- Benefits: Provides reliable and consistent performance across various uses.

High-Performance Twin Screw Extruder

- Description: Designed for applications requiring enhanced control and precision.

- Benefits: Ensures high efficiency and reliability in demanding environments.

Customizable Twin Screw Extruder

- Description: Tailored to meet specific application requirements.

- Benefits: Offers flexibility and precision for specialized processes.

Applications

Plastics Industry

- Usage: Used for processing and mixing plastic materials.

- Benefits: Ensures consistent quality and high productivity.

Rubber Industry

- Usage: Ideal for mixing and extruding rubber compounds.

- Benefits: Provides uniform mixing and efficient processing.

Food Industry

- Usage: Suitable for extruding food products such as snacks and cereals.

- Benefits: Ensures safe and hygienic processing.

Accessories and Tools Included

Essential Accessories

- Mixing Augers: High-quality dual-sided mixing screws for efficient mixing.

- Extruding Dies: Stainless steel dies with multi-dimensional capabilities.

Additional Tools

- Cleaning Kit: Ensures easy maintenance and cleaning of the extruder.

- User Manual: Provides detailed instructions for operation and maintenance.

Spares Kit

- Contents: Set of spare parts and fittings including a 10-foot long flexible pipe, six Inconel rupture discs/valves, and different gaskets.

Installation and Training

Comprehensive Installation Services

- Process: Complete installation and setup by factory-trained engineers.

- Seamless Integration: Ensures smooth integration into your production facility, minimizing downtime.

Thorough Training Programs

- Training: Extensive training for your staff on operating and maintaining the twin screw extruder.

- Benefits: Maximizes productivity and efficiency by ensuring your team is proficient in using the extruder.

Warranty

Limited Warranty

- Duration: 12 months limited warranty on parts and after-sales services.

- Exclusions: Excludes consumables, user-damaged parts, and damages caused by improper handling.