3D Jacquard Socks Knitting Machine

Advanced Socks Knitting Solution

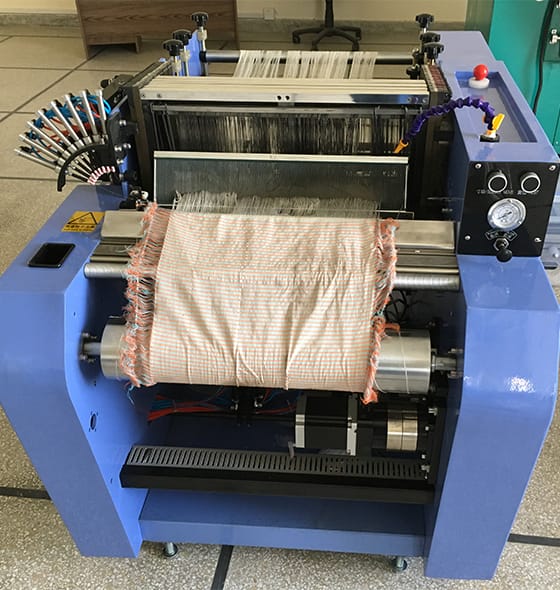

MAGICA Full Electronic Single Cylinder 3D Jacquard Machine

Product Introduction

The MAGICA 3D Jacquard Socks Knitting Machine is a high-performance, fully electronic single-cylinder machine designed for the production of true argyle socks for men, women, and children. Engineered with state-of-the-art technology, this knitting machine offers unparalleled precision, efficiency, and versatility. It is ideal for both large-scale manufacturing and specialized sock production, ensuring consistent and high-quality results.

Key Features

Advanced Knitting Technology

- Full Electronic Control: Operated by an onboard microcomputer for precise control.

- 3D Jacquard Capabilities: Produces intricate and detailed argyle patterns with ease.

- 4 Feeds: Ensures efficient and high-speed knitting.

Robust Construction

- Brushless Main Motor: Provides reliable and efficient performance with minimal maintenance.

- Durable Materials: Constructed with high-quality components to withstand rigorous use.

User-Friendly Design

- Easy Operation: Intuitive controls and interface for straightforward setup and operation.

- Automatic Machine Resetting: Resets in 3 seconds for minimal downtime.

Versatile Applications

- Wide Range of Sizes: Electronical size control for 8 different sizes.

- Customizable Stitch Quality: Programmable stitch quality with 127 steps motor for precise adjustments.

Specifications Table

| Feature | Specification |

|---|---|

| Machine Type | Full Electronic Single Cylinder |

| Production Capability | True Argyle Socks for Men, Women, and Children |

| Design and Thinking | 4 Feeds |

| Motor | Brushless Main Motor |

| Control | Electronically Controlled by Onboard Microcomputer |

| Yarn Fingers | 18 Electro-Pneumatic Yarn Fingers |

| Rubber Yarn Finger | With Positive Feeder Electronically Controlled by Step-by-Step Motor |

| Actuators | 8 Groups of Actuators for Needle-by-Needle Selection |

| Stitch Quality | Programmable by 127 Steps Motor |

| Heel and Toe | Without Picker and Dropper |

| Needle Breakage Detection | Machine stops with broken needle ready for replacement |

| Function Control | Check control for all functions and trouble detection |

| Size Control | Electronical size control (8 sizes) |

| Cutter | Operates only during operation |

| Automatic Resetting | 3 seconds |

Types of Knitting Machines

Standard Socks Knitting Machine

- Description: Ideal for general-purpose sock production.

- Benefits: Provides reliable and consistent knitting for various sock designs.

High-Performance Knitting Machine

- Description: Designed for high-speed and high-volume production.

- Benefits: Ensures efficient and large-scale manufacturing of socks.

Custom Pattern Knitting Machine

- Description: Specifically engineered for producing custom patterns and designs.

- Benefits: Delivers intricate and high-quality patterned socks.

Applications

Fashion and Apparel

- Usage: Used in the production of fashionable and high-quality socks.

- Benefits: Ensures consistent quality and design accuracy for fashion brands.

Sports and Performance

- Usage: Ideal for producing performance socks for sports and active wear.

- Benefits: Provides durable and comfortable socks with specialized features.

Medical and Therapeutic

- Usage: Suitable for knitting medical and therapeutic socks.

- Benefits: Ensures precise construction for specialized medical applications.

Accessories and Tools Included

Essential Accessories

- Yarn Feeders: 18 electro-pneumatic yarn fingers for precise yarn control.

- Needle Selection Actuators: 8 groups for accurate needle-by-needle selection.

Additional Tools

- Cleaning Kit: Ensures easy maintenance and cleaning of the machine.

- User Manual: Provides detailed instructions for operation and maintenance.

Installation and Training

Comprehensive Installation Services

- Process: Complete installation and setup by factory-trained engineers and technicians.

- Seamless Integration: Ensures smooth integration into your production facility, minimizing downtime and maximizing efficiency.

Thorough Training Programs

- Training: Extensive training for your staff, covering operational and maintenance aspects.

- Benefits: Maximizes productivity and efficiency by ensuring your team is well-versed in using the knitting machine.

Warranty

Limited Warranty

- Duration: 12 months limited warranty on parts and after-sales services.

- Exclusions: Excludes consumables, user-damaged parts, and damages caused by electrical failures, fire, or natural disasters.