Vacuum Infusion Fabrication System

Advanced Vacuum Infusion Table

High-Quality Vacuum Infusion Machine

Introduction

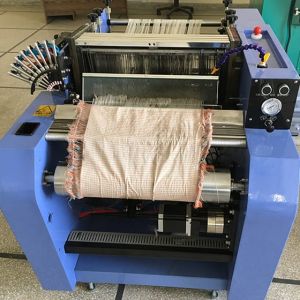

The Vacuum Infusion Fabrication System is an essential tool for composite manufacturing, ensuring superior quality and efficiency. This advanced setup is designed for professionals seeking precision and reliability in vacuum infusion processes. It is ideal for fabricating large composite parts with high strength-to-weight ratios, widely used in aerospace, automotive, and marine industries.

Key Features

- Robust Construction: Made from fully stainless steel (SS) for durability and corrosion resistance.

- Optimal Size: The table measures approximately 6 feet, providing ample workspace.

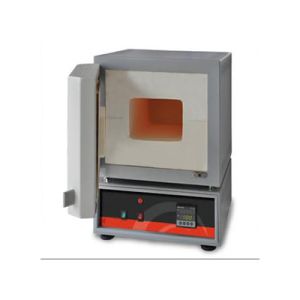

- Heating Plates: Equipped with two separate 2 x 2 feet heating plates, allowing precise temperature control for optimal resin curing.

- Advanced Heating System: Features built-in heaters to maintain consistent temperatures.

- Comprehensive Control: Includes an easy-to-use control box with on/off switches, emergency off button, temperature controller (+/-), and temperature gauge.

- Vacuum and Resin Management: Comes with vacuum gauge and resin pot specifications, including two 500 ml pots with input and output nozzles.

- Reliable Wiring: Ensures safe and efficient operation.

- Vacuum Pump: High-efficiency vacuum pump for consistent and reliable vacuum pressure.

- Digital Display: Digital display for precise monitoring of temperature and vacuum levels.

- Adjustable Legs: Height-adjustable legs for ergonomic working conditions.

- Storage Compartments: Built-in storage compartments for tools and materials.

Specifications

| Specification | Details |

|---|---|

| Table Material | Fully Stainless Steel |

| Table Size | About 6 feet (customizable) |

| Heating Plates Size | 2 x 2 Feet working area (2 separate plates) (customizable) |

| Heating System | Heaters |

| Control Box | On/Off, Emergency Off, Temperature Controller (+/-), Temperature Gauge |

| Vacuum Gauge | Included |

| Wiring | Safe and efficient |

| Resin Pot | No. 2 Pots (500 ml) with 2 nozzles (input & output) (customizable) |

| Vacuum Pump | High-efficiency vacuum pump (as per need) |

| Digital Display | For precise monitoring |

| Adjustable Legs | Height-adjustable |

| Storage Compartments | Built-in for tools and materials |

Applications

The Vacuum Infusion Fabrication System is suitable for:

- Aerospace components

- Automotive parts

- Marine structures

- Wind turbine blades

- High-performance sporting goods

Installation and Training

Professional installation and training services ensure seamless integration into your manufacturing process, maximizing productivity and efficiency.

Warranty Information

This system comes with a comprehensive warranty to provide peace of mind and ensure long-term reliability.