Injection Molding Machine for Rubber

Advanced Rubber Molding Solution

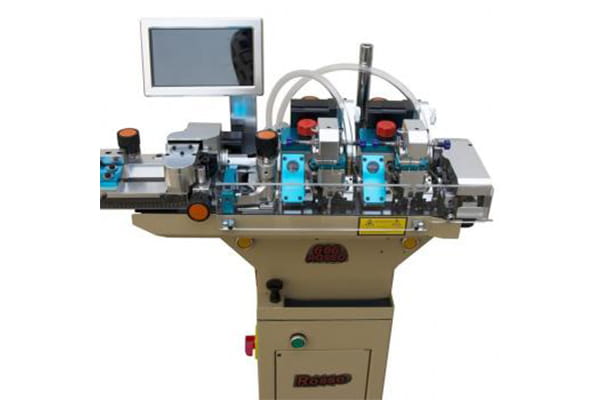

High-Performance Injection Molding Machine

Product Introduction

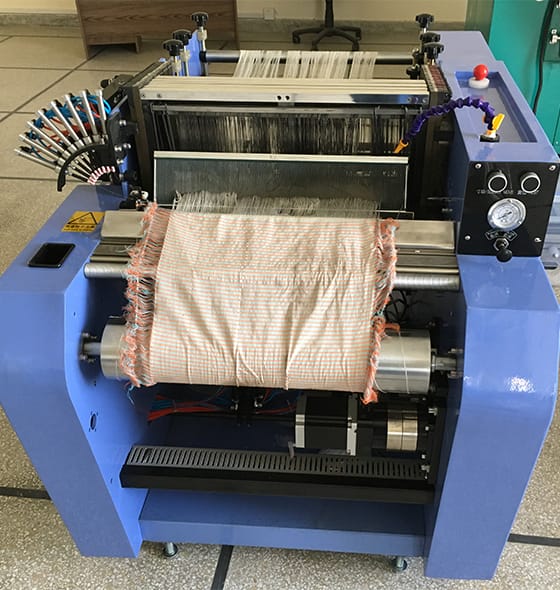

The Injection Molding Machine for Rubber by Marjan Polymer Industries is a state-of-the-art equipment designed for high-precision rubber molding applications. This machine is engineered to provide efficient and reliable performance, making it ideal for both small-scale and large-scale production in the rubber manufacturing industry. With advanced features and robust construction, it ensures consistent quality and high output, catering to various industrial needs.

Key Features

Superior Molding Precision

- High Efficiency: Ensures precise molding of rubber products, delivering consistent and high-quality results.

- Versatile Applications: Suitable for a wide range of rubber molding applications, offering flexibility in various industrial processes.

Robust Construction

- Durable Materials: Constructed with high-quality materials to withstand rigorous use and ensure long-lasting performance.

- Intense Mixer Included: Equipped with an intense mixer for better mixing and homogenization of rubber materials.

User-Friendly Design

- Easy Operation: Intuitive controls and interface for easy setup and operation.

- Automatic Functions: Includes automatic functions for enhanced efficiency and productivity.

Versatile Applications

- Wide Range of Uses: Ideal for automotive, industrial, and consumer rubber products manufacturing.

Specifications Table

| Feature | Specification |

|---|---|

| Type | 50-100T |

| Pressure | 50-100 tons |

| Clamping Force | 500-1000KN |

| Motor | 10-15Kw |

| Bore Diameter | 320-380mm |

| Open Mold Stroke | 350-400mm |

| Platen Size | 600mm×600mm |

| Heating Method | Electric heating |

| Temperature Distribution | + 2ºC |

| Ram | CR white special alloy metals |

| Injection System | DingFeng (TAIWAN) |

| PLC | Programmable controller Japan |

| Overall Dimensions (L×W×H) | 8×6×8ft |

| Screw Diameter | 30-50mm |

| Screw Speed | 0-90 rpm |

Types of Injection Molding Machines

Standard Injection Molding Machine

- Description: Ideal for general-purpose rubber molding applications.

- Benefits: Provides reliable and consistent performance across various uses.

High-Performance Injection Molding Machine

- Description: Designed for applications requiring enhanced control and precision.

- Benefits: Ensures high efficiency and reliability in demanding environments.

Customizable Injection Molding Machine

- Description: Tailored to meet specific application requirements.

- Benefits: Offers flexibility and precision for specialized processes.

Applications

Automotive Industry

- Usage: Used in the production of automotive rubber parts.

- Benefits: Ensures high quality and precision for critical automotive components.

Industrial Products

- Usage: Ideal for manufacturing industrial rubber products.

- Benefits: Provides consistent quality and durability for industrial applications.

Consumer Goods

- Usage: Suitable for producing consumer rubber products such as seals, gaskets, and footwear.

- Benefits: Delivers high-quality and reliable products for consumer use.

Accessories and Tools Included

Essential Accessories

- Mixing Tools: Intense mixer for efficient material mixing.

- Heating Elements: High-quality electric heating elements for precise temperature control.

Additional Tools

- Cleaning Kit: Ensures easy maintenance and cleaning of the machine.

- User Manual: Provides detailed instructions for operation and maintenance.

Installation and Training

Comprehensive Installation Services

- Process: Complete installation and setup by factory-trained engineers.

- Seamless Integration: Ensures smooth integration into your production facility, minimizing downtime and maximizing efficiency.

Thorough Training Programs

- Training: Extensive training for your staff, covering operational and maintenance aspects.

- Benefits: Maximizes productivity and efficiency by ensuring your team is well-versed in using the injection molding machine.

Warranty

Limited Warranty

- Duration: 12 months limited warranty on parts and after-sales services.

- Exclusions: Excludes consumables, user-damaged parts, and damages caused by electrical failures, fire, or natural disasters.